Issue Date:September 17, 2025

Employees are the key driving force behind the Company’s continuous innovation and sustainable development. Therefore, it is the Company’s responsibility to provide a safe working environment. Coretronic takes “building a safe and healthy workplace” and “zero occupational accidents” as the management goals of a safe working environment, with the aim of ensuring that all Coretronic employees and workers can perform their duties in a healthy and safe environment.

Occupational Safety and Health Management System

Coretronic fully institutionalizes environmental safety and health management regulations for employees and workers to follow, formulates the Occupational Safety and Health Policy, regularly reviews safety and health performance. The Company also strengthens personnel education and training and implements risk management and regular on-site inspections to ensure the safety of the work environment. In 2024, the internal and external verification scope of the occupational health and safety management system covers the number of employees and workers reported in the “Occupational Accident Management”.

In addition to implementing and introducing hazard prevention measures and related management regulations by national laws and regulations and the nature of different workplaces, the top supervisor establishes a safety and health organization and an Occupational Safety and Health Committee. Occupational safety and health personnel in each plant are responsible for the third-party certification (ISO 45001) inspection of the occupational safety and health management system. The certification passing rate of Taiwan plants, Wujiang plants, and Coretronic Projection (Kunshan)1 is 100%. Under the ISO 45001 management system, internal audits2 covered 4,030 employees and 502 non-employees, achieving a 100% audit coverage rate. External audits covered 3,937 employees and 444 non-employees, with coverage rate of 98% and 88% respectively. Taiwan plants have also simultaneously obtained the CNS 45001 certificate. It is hoped that by implementing the work plans of each management cycle, the purpose of continuous improvement can be achieved, the occurrence of occupational accidents can be reduced, and the safety and health of all employees and stakeholders can be ensured.

1: Coretronic Optics (Kunshan) is the upstream supplier of Coretronic Projection (Kunshan), and their work environment safety systems are jointly managed. In the future, it will pass the ISO 45001 certification according to customer needs.

2: Employee and worker numbers cited in this section are rounded averages from January to December 2024; for Taiwan plants, they are based on reported occupational accident statistics from January to December 2024; those for China plants, they are based on HR system data.

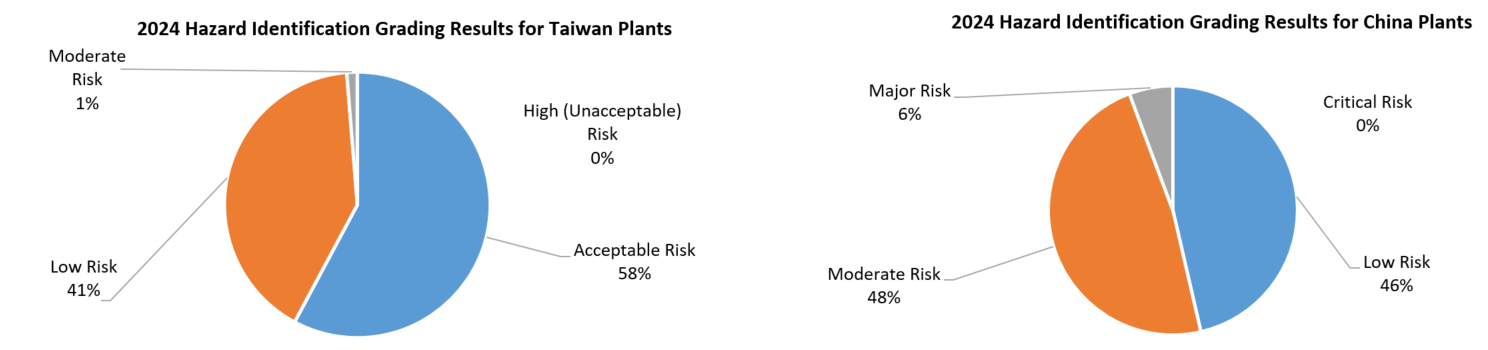

Occupational Safety Risk Management

Coretronic has established hazard identification and risk assessment operation specifications, and the management unit promotes each department to regularly review and revise hazard identification and risk assessment data every year. Before manufacturing process, equipment, raw materials, and working environment are changed, hazard identification is conducted according to chemical, physical, ergonomic, biological, and other safety and health (including social and psychological) hazards, and personnel related to the implementation of hazard identification and risk assessment are required to receive at least three hours of risk assessment related training. Each department classifies different work environments, equipment or manufacturing processes, conducts job and operation inspections according to possible hazards, and cooperates with the operation process of each department to expand and fill in each operation step in the “Hazard Identification and Risk Assessment Form”. Based on the severity and probability, the risk level is converted, and risk control is judged and adopted. For the higher risk hazard factors of each plant in the year, improvement plans are formulated and continuous improvement is carried out to provide employees and workers with a good work safety environment. If a major occupational accident occurs, it will be listed as a high-risk level and risk control will be carried out. In 2024, Taiwan and China plants have all completed risk assessments for various operations, with no unacceptable risks or critical risks.

Referring to the local government occupational safety and health regulations in Taiwan and China, when there is an immediate danger in the workplace, the employer or the person in charge of the workplace needs to stop the operation and have employees evacuate to a safe place. If employees believe that the duties they perform have potential hazard risks, they can stop the operation and evacuate to a safe place on their own without endangering the safety of other workers, and immediately report to their direct supervisor. For employees who actively report and evacuate due to occupational safety hazard concerns, it is stated in the relevant operation specifications that they will not be punished.

Occupational Safety and Health Organization

Coretronic’s Taiwan and China plants have occupational safety and health management units responsible for planning, supervising, and promoting labor safety and health related business. To smoothly promote and implement safety and health work, the PDCA management mechanism is used to continuously improve the risks of personnel, equipment, and environment, enhance employees' self-safety awareness, and jointly achieve the goal of zero accidents.

Occupational Safety Consultation, Participation, and Communication

To foster a safe and comfortable environment and promote communication between labor and management, Coretronic’s Taiwan plants regularly convene “Occupational Safety and Health Committee” meetings, and China plants also regularly hold “Occupational Health Management Committee” and “Safety Regular Meetings”. The committee members are composed of supervisors at all levels, safety and health personnel, and labor representatives. Their responsibilities are to put forward suggestions on the Company’s Occupational Safety and Health Policy, and to review, coordinate, and suggest safety and health related matters. Meetings are held quarterly to jointly decide on the planning and operation of the safety and health system, and the results are announced in paper or electronic form. All employees are encouraged to put forward occupational safety related suggestions through the “Environmental, Safety and Health (ESH) Opinion Platform”, and the management unit actively assists upon receiving notification, and the suggester will not be punished; contractors communicate occupational safety issues through the annual agreement organization meeting for advocacy, consultation, and communication.

【Matters promoted for discussion and consultation】

- Continue to promote a safe working environment and prevent occupational accidents

- Continue to promote energy conservation, carbon reduction, and industrial waste reduction in the plant

- Regularly conduct education and training to enhance employee safety and health awareness

- Continue to promote environmental safety audits

- Management review to ensure the effective operation of the ESH management system

【2024 Occupational Safety and Health Committee meetings for Taiwan】held the meetings quarterly, the labor representatives are as follows:

| Taiwan Plants | Number of labor representatives | Total number of committee members | Proportion |

|---|---|---|---|

| Headquarters | 5 | 12 | 42% |

| Chunan Plant | 10 | 23 | 43% |

| Tainan Plant 1 | 8 | 22 | 36% |

| Tainan Plant 2 | 3 | 9 | 33% |

| China Plants | Number of labor representatives | Total number of committee members | Proportion |

|---|---|---|---|

| Kunshan Plants | 4 | 17 | 24% |

| Wujiang Plants | 6 | 17 | 35% |

Occupational Safety and Health Education and Training

| Training Item / 地區 | Taiwan | China |

|---|---|---|

| Occupational Safety Training for New Employees (participants) | 307 | 3,335 |

| Annual Fire/Civil Defense Team Training (participations) | 378 | 5,888 |

| Occupational Safety and Health On- the-job Training (participations) | 3,196 | 6,951 |

| Annual Contractor Onboarding Training (participants) | 492 | 62 |

| Total Training Participations | 4,373 | 16,236 |

| Total Training Hours | 7,704 | 98,009 |

Disaster Response Drills

Occupational Accident Management

- Based on the results of the annual material topic, Coretronic sets “reducing the number of occupational injuries” as the goal of “Occupational Health and Safety”, and implements related actions. To reduce the incidence of occupational accidents, the Company has implemented a systematic approach to managing occupational accident risks. In addition to establishing the Occupational Injury and Accident Management Operation Specifications, the Company has set up a platform for “Accident Report/Personnel Occupational Injury/ESH Anomaly Incident Handling Record” to document and track the causes of incidents and the corresponding corrective actions. Whenever an occupational injury occurs, the relevant hazard factors are re-assessed and risks re-evaluated to strengthen preventive measures. Regular internal inspections and adherence to accident management specifications and reporting systems ensure thorough analysis and continual improvement of workplace safety.

- At Taiwan plants, there were 5 close calls and 5 occupational injury accidents (excluding traffic accidents) in 2024. These included 4 cases of employees tripping while walking and 1 case of a muscle strain due to improper lifting posture. All cases underwent incident analysis, followed by corrective and preventive actions such as safety awareness campaigns and training on walking, stair usage, and lifting techniques to raise individual safety awareness and reduce recurrence.

- From March 27, 2019, to December 31, 2024, the Chunan Plant averaged 295 monthly participants in the Industrial Safety and Health Association’s autonomous safety and health management campaign—“Zero Accident Hours Record Activity”. As of the end of 2024, the plant had accumulated 3,236,072 hours without a recorded workplace injury. The plant will continue striving toward its goal of “zero workplace accidents”, maintaining a safe work environment.

- At China plants, there were 6 close calls and 5 occupational injury accidents (excluding traffic accidents) in 2024. These included 1 fall, 2 cuts, and 1 sprain case at Wujiang plants, and 1 fall case at Kunshan plants. All incidents were thoroughly investigated and followed up with safety awareness campaigns, successfully meeting 2024 targets. To further reduce workplace injuries, Wujiang plants enhanced safety training and awareness on automated production equipment operations, strengthened 7S practices and conducted regular safety inspections. Kunshan plants focused on promoting safe stair use and discouraging mobile phone use while walking to prevent accidents.

Annual Work-related Injuries Records of Employees5

| Region | Taiwan6 | China6 | ||||||

|---|---|---|---|---|---|---|---|---|

| Item/Year | 2021 | 2022 | 2023 | 2024 | 2021 | 2022 | 2023 | 2024 |

| Total Working Hours | 2,896,536 | 3,019,048 | 3,018,456 | 2,913,152 | 8,167,136 | 9,153,560 | 6,062,224 | 5,255,704 |

| Rate of Fatalities as a Result of Work-Related Injury1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Number of High-Consequence Work-Related Injuries (excluding fatalities)2 | 0 | 0 | 0 | 0 | 13 | 11 | 2 | 5 |

| Rate of High-Consequence Work-Related Injuries (excluding fatalities)2 | 0 | 0 | 0 | 0 | 1.6 | 1.2 | 0.3 | 1.0 |

| Lost Workdays Due to Disabling Injuries | 0 | 5 | 3 | 35 | 365 | 691 | 66 | 216 |

| Number of Recordable Work-Related Injuries3 | 2 | 8 | 7 | 10 | 13 | 14 | 8 | 11 |

| Rate of Recordable Work-Related Injuries3 | 0.7 | 2.6 | 2.3 | 3.4 | 1.6 | 1.5 | 1.3 | 2.1 |

| Lost-Time Injury Frequency Rate4 | 0 | 0.3 | 0.3 | 1.7 | 1.6 | 1.5 | 1.3 | 2.1 |

| 1. Rate of fatalities as a result of work-related injury: Calculated as (Number of fatalities as a result of work-related injury/Total working hours) × 1,000,000. 2. Rate of high-consequence work-related injuries (excluding fatalities): Calculated as (Number of high-consequence work-related injuries (excluding fatalities)/Total working hours) × 1,000,000. “High-consequence work-related injuries” refer to incidents classified as major accidents according to the “Occupational Injury and Accident Management Operation Guidelines”. 3. Rate of recordable work-related injuries: Calculated as (Number of recordable work-related injuries/Total working hours) × 1,000,000. At Taiwan plants, “recordable work-related injuries” include cases that must be reported as per the Occupational Safety and Health Administration's announcements, encompassing both occupational injuries and close calls. At China plants, the figures are recorded based on company regulations. 4. Lost-Time Injury Frequency Rate = number of lost-time injuries/total hours worked in accounting period x 1,000,000 5. Employee Numbers and Working Hours Statistics: The number of employees is based on the average number from January to December 2024, rounded to the nearest whole number. For Taiwan plants, calculations are based on occupational injury reporting data from January to December 2024. For China plants, calculations are based on data from the human resources system. In 2024, the total number of employees was 4,030. 6. From 2021 to 2023, Taiwan plants include Coretronic (Headquarters, Chunan Plant, Tainan Plant 1, and Tainan Plant 2); China plants include Kunshan plants (Coretronic Projection (Kunshan), Coretronic Optics (Kunshan)) and Wujiang plants (Coretronic Display (Suzhou), Coretronic Optotech (Suzhou), and Coretronic Optics (Suzhou)). In 2024, Taiwan plants include Coretronic (Headquarters, Chunan Plant, Tainan Plant 1, and Tainan Plant 2); China plants include Kunshan plants (Coretronic Projection (Kunshan), Coretronic Optics (Kunshan)) and Wujiang plants (Coretronic Optotech (Suzhou), and Coretronic Optics (Suzhou)). |

||||||||

| Region | Taiwan6 | China6 | ||||||

|---|---|---|---|---|---|---|---|---|

| Item/Year | 2021 | 2022 | 2023 | 2024 | 2021 | 2022 | 2023 | 2024 |

| Total Working Hours | 196,664 | 435,944 | 181,528 | 244,016 | 8,226,264 | 2,971,928 | 880,160 | 775,184 |

| Rate of Fatalities as a Result of Work-Related Injury1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Number of High-Consequence Work-Related Injuries (excluding fatalities)2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Rate of High-Consequence Work-Related Injuries (excluding fatalities)2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Lost Workdays Due to Disabling Injuries | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Number of Recordable Work-Related Injuries3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Rate of Recordable Work-Related Injuries3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Lost-Time Injury Frequency Rate4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 1. Rate of fatalities as a result of work-related injury: Calculated as (Number of fatalities as a result of work-related injury/Total working hours) × 1,000,000. 2. Rate of high-consequence work-related injuries (excluding fatalities): Calculated as (Number of high-consequence work-related injuries (excluding fatalities)/Total working hours) × 1,000,000. “High-consequence work-related injuries” refer to incidents classified as major accidents according to the “Occupational Injury and Accident Management Operation Guidelines”. 3. Rate of recordable work-related injuries: Calculated as (Number of recordable work-related injuries/Total working hours) × 1,000,000. At Taiwan plants, “recordable work-related injuries” include cases that must be reported as per the Occupational Safety and Health Administration's announcements, encompassing both occupational injuries and close calls. At China plants, the figures are recorded based on company regulations. 4. Lost-Time Injury Frequency Rate = number of lost-time injuries/total hours worked in accounting period x 1,000,000 5. Non-Employee Worker Numbers and Working Hours Statistics: The number of employees is based on the average number from January to December 2024, rounded to the nearest whole number. For Taiwan plants, calculations are based on occupational injury reporting data from January to December 2024. For China plants, calculations are based on data from the human resources system. In 2024, the total number of non-employees workers was 502. 6. From 2021 to 2023, Taiwan plants include Coretronic (Headquarters, Chunan Plant, Tainan Plant 1, and Tainan Plant 2); China plants include Kunshan plants (Coretronic Projection (Kunshan), Coretronic Optics (Kunshan)) and Wujiang plants (Coretronic Display (Suzhou), Coretronic Optotech (Suzhou), and Coretronic Optics (Suzhou)). In 2024, Taiwan plants include Coretronic (Headquarters, Chunan Plant, Tainan Plant 1, and Tainan Plant 2); China plants include Kunshan plants (Coretronic Projection (Kunshan), Coretronic Optics (Kunshan)) and Wujiang plants (Coretronic Optotech (Suzhou), and Coretronic Optics (Suzhou)). |

||||||||

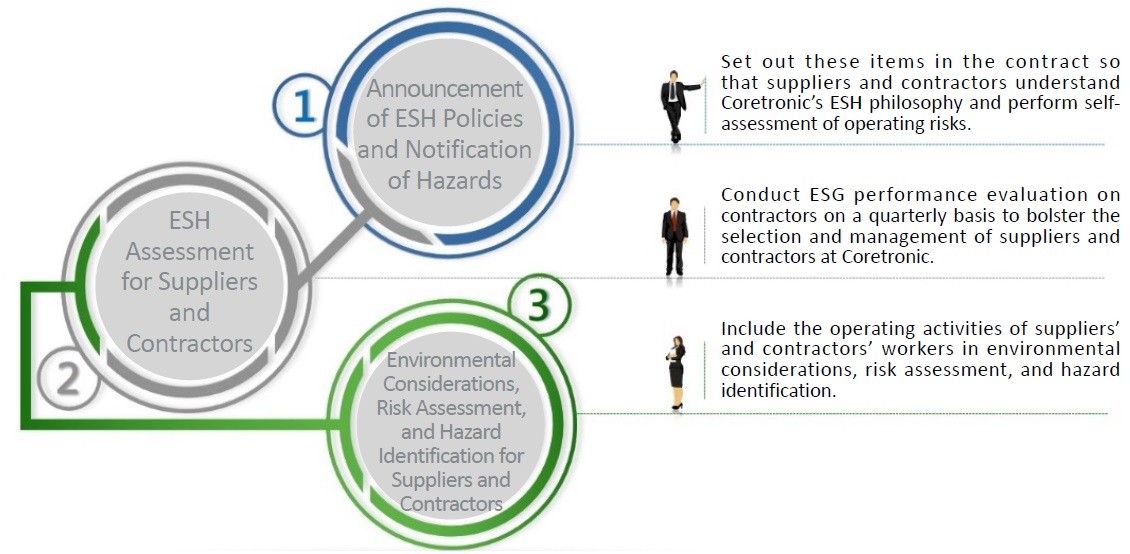

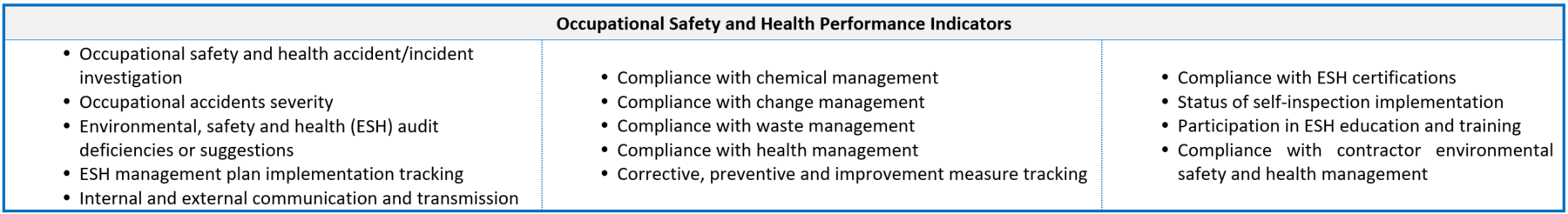

Contractor Management

In addition to employees, contractors are also important partners of Coretronic. To safeguard the health of its partners, ensure facility safety, and concretely fulfill Coretronic’s commitment to workplace health and safety, Taiwan plants have established clear operational procedures for supplier and contractor management. Regular contractor evaluations are conducted to ensure compliance with on-site regulations. The Company also places great emphasis on communication and hazard notification for non-employee workers. All contractors are required to participate in a “Contractor Workplace Hazard Notification and Agreement Meeting” before entering the plant, and all construction personnel must complete Coretronic’s “Contractor ESH Education and Training”. Furthermore, construction applications and the management of pre-, mid-, and post-construction stages are effectively controlled through a digital construction application system.

Through the effective implementation of contractor safety and health management, Taiwan plants have achieved zero contractor incidents for 10 consecutive years (2015~2024), and China plants have maintained zero contractor incidents for 3 consecutive years (2022~2024).