R&D and Technology of Light Modules

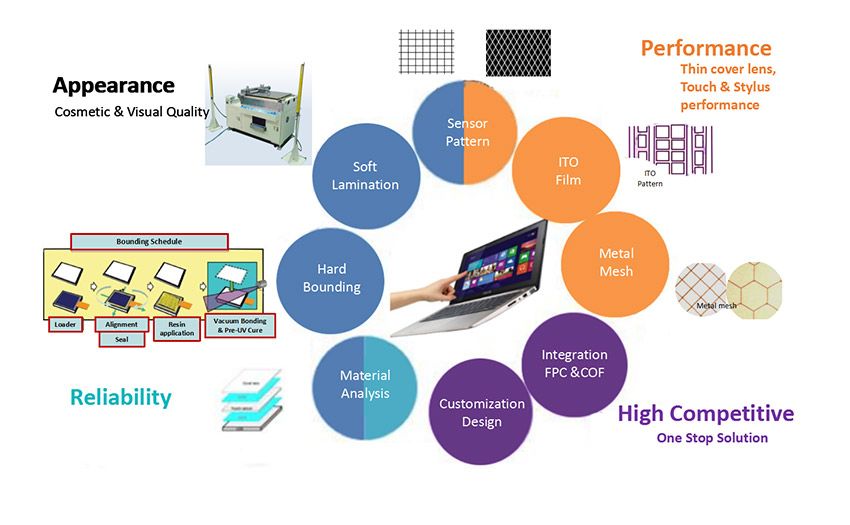

Coretronic invested years of research and development touch display applications. Provide customized touch panel and LCM (Direct bonding) for the full range of integrated services. The past two years, we continue to expand our production capacity and increase the manufacturing yield, cooperation with customers to achieve strategic goals.

Our advantages include: conductive films touch the product design and development, optical clear resin(OCR) process capability and touch controller with parameter adjustment conductive films, etc. Providing customers with high transmittance, high sensitivity, abrasion steady touch module products, and applications in Smart Phone, Tablet, NB, and AIO, etc.

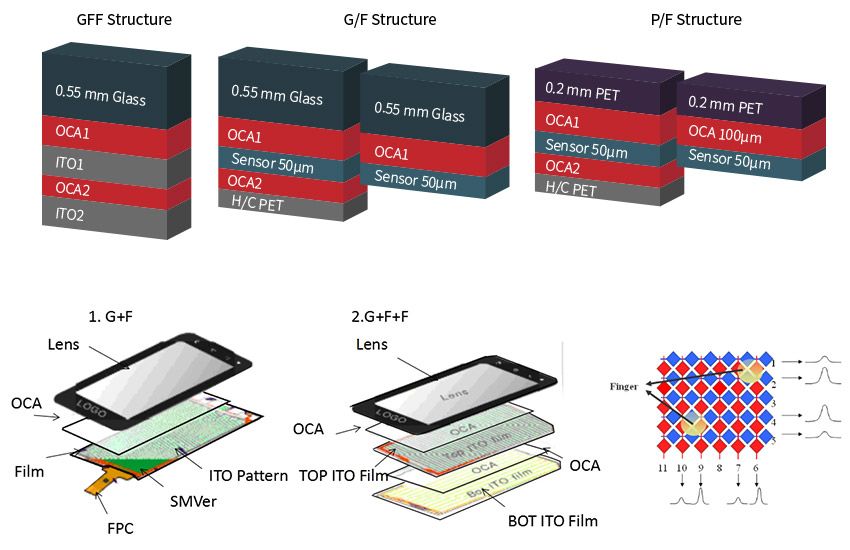

TP Technology & Structure

TP Narrow Border

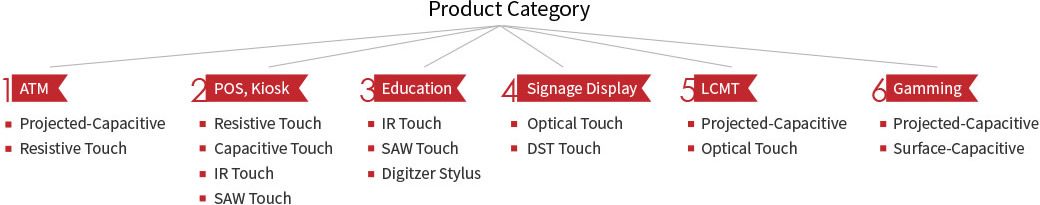

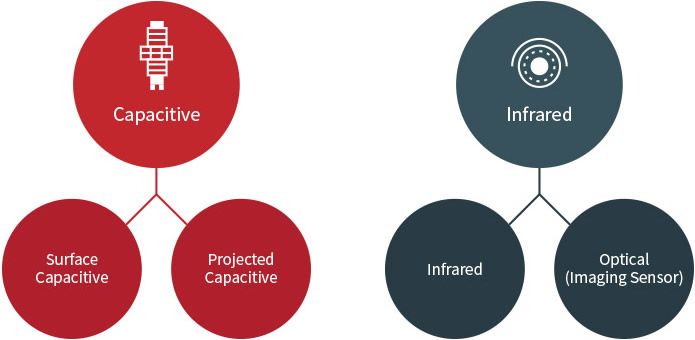

TP Technology Application

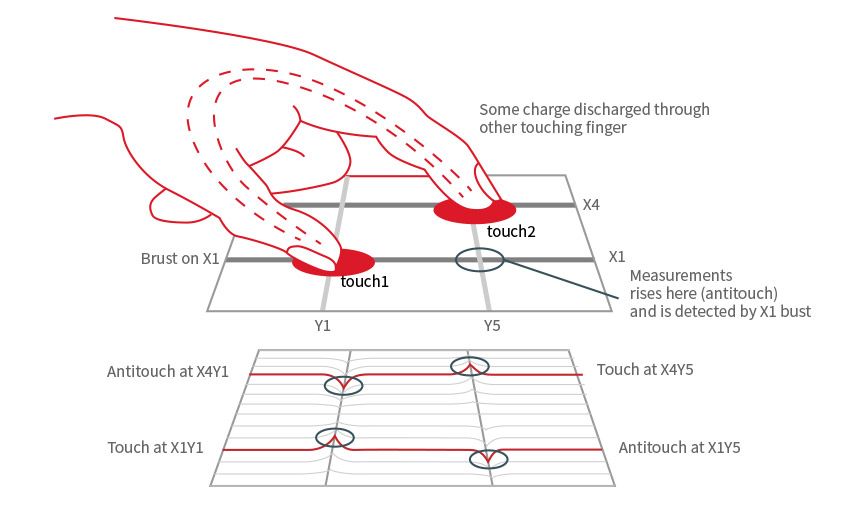

Currently, we are focusing on "projected capacitive" and are able to produce 28'' touch screen Further Development:

Automotive Touch Screen

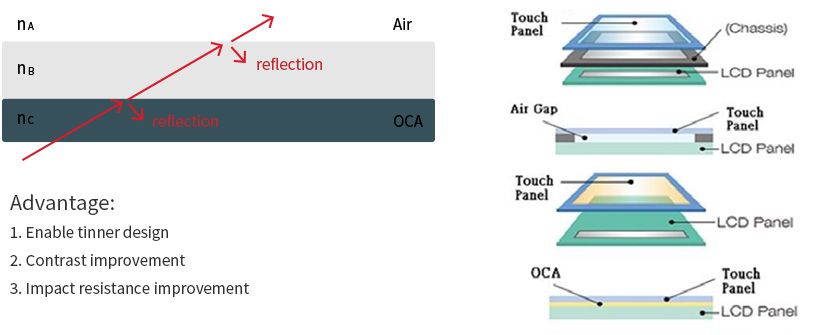

Surface Bonding

Slim Touch Panel

Transparent Conductive Film

Touch Product Technology

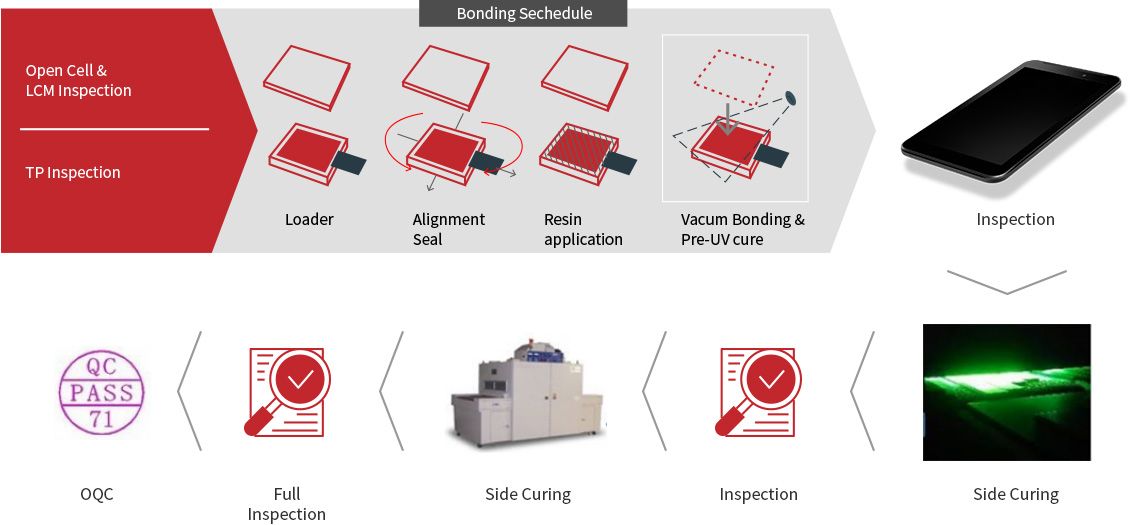

Direct Bonding Process Flow

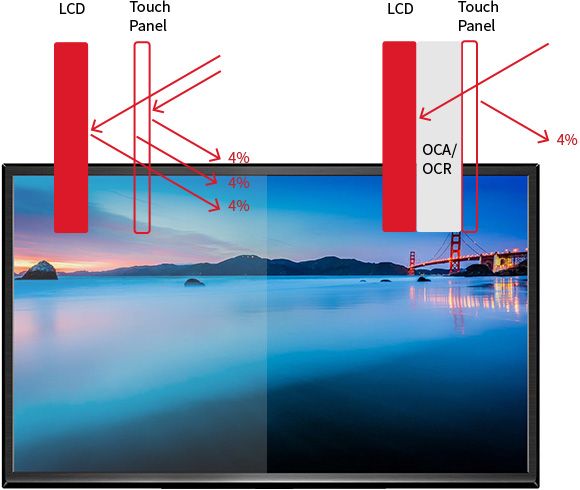

Direct Bonding Performance

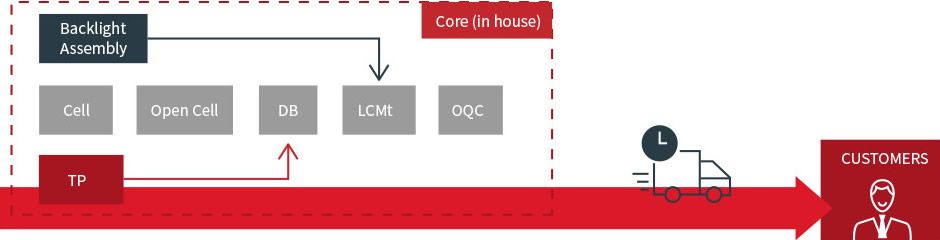

Touch Module Train Service

This approach differs from general industry to achieve vertical integration solutions and provide customers total solution and customized.

General process

New integration process