Technology

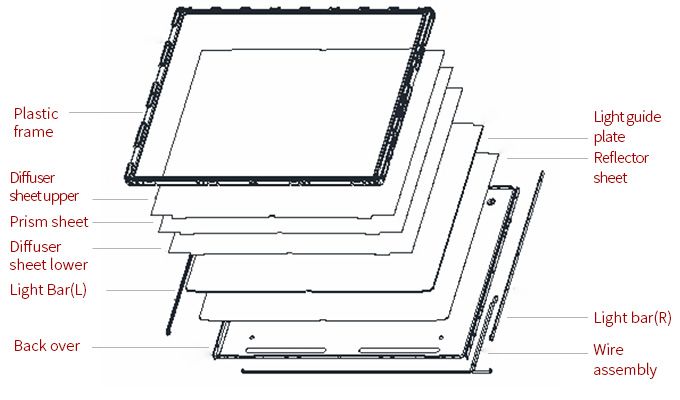

Backlight Module, the light source of TFT-LCD, is constructed by optical films, light guide plate, LED light bar, back-cover and plastic case. Because the liquid crystal molecule only function as the penetration level that doesn't illuminate spontaneously, it is necessary to add a backlight module to distribute the light that make us to see the beautiful scene on the screen. Thus, backlight module is the key part for TFT-LCD. Not only as the light source of TFT-LCD, backlight module is also critical to brightness, uniformity, formation, and view angel of LCD.

Structure

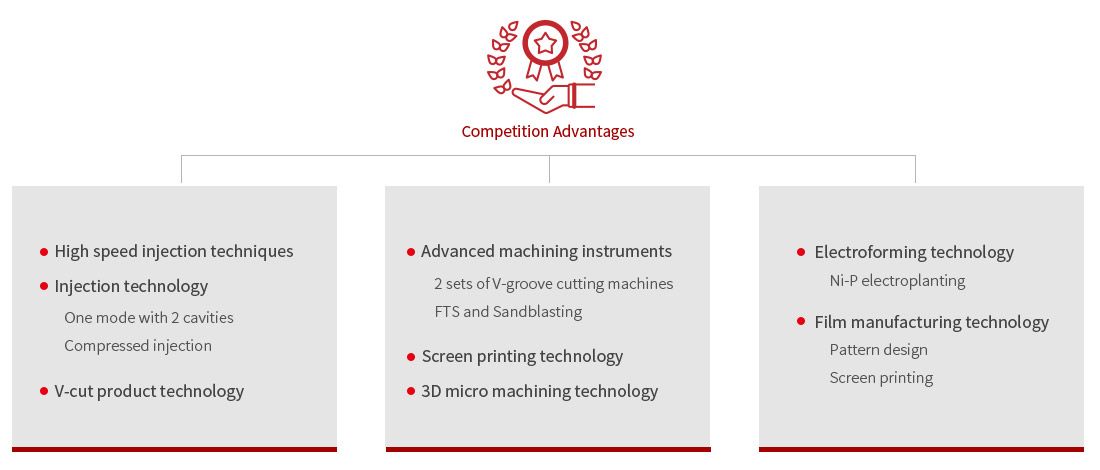

Our backlight module business has a strong R&D technology group and is at the leading position in precision technology of optical components. We provide OEM and ODM manufacturing services of backlight modules and display products for WW customers. We also provide service of processing, including printing, cutting, injection, on the related components of backlight modules such as light guide plates and optical films. We have patents on critical technologies, including the technology of Light Guide Plate Injection, inkjet, roller stamping, Prism and Diffuser sheet Cutting, Printing, Micro Precision process, Electro-forming, Laser, Sand Blasting, Wire Winding, IPO Electroplating, V-cut Process. Combining our outstanding operations and R&D teams, supported by professional management and specialists, these professionals of the Coretronic Backlight Unit Business Group have integrated supply chain and marketing systems to provide the highest quality products and services to our esteemed customers.

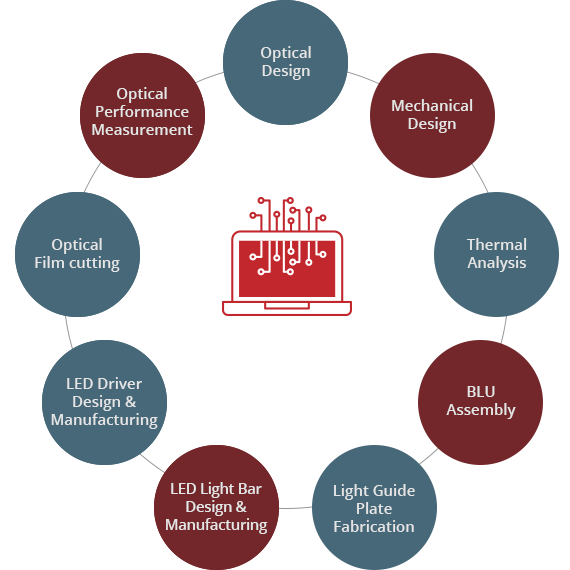

Core technology

- Optical Design

- Mechanical Design

- Thermal Analysis

- BLU Assembly

- Light Guide Plate Fabrication

- Light Guide Plate injection process: high precision pattern design, high precision mold design, high precision injection.

- Light Guide plate printing process: halftone printing, ink-jet printing technology.

- Light Guide Plate laser pattern technology.

- Light Guide Plate microstructure pattern technology.

- Light Guide Plate roller stamping process.

- LED Light Bar Design & Manufacturing

- LED Driver Design & Manufacturing

- Optical Film Cutting

- Optical Performance Measurement.