Issue Date: August 09, 2024

As employees are the key driver for continuous innovation and sustainable development at a company, providing employees with a safe workplace is the responsibility of a company. With “building a safe and healthy workplace” and “zero occupational disaster” as our safe workplace management targets, we endeavor to ensure that employees and workers at Coretronic are able to work in a healthy and safe workplace.

Occupational Safety and Health Management System

We fully institutionalize environmental safety and health management regulations for employees and workers to follow, and formulate safety and health policies, regularly review safety and health performance, strengthen personnel education and training, implement risk management and regular on-site inspections to ensure the safety of the work environment. In 2023, the internal and external verification scope of the occupational health and safety management system covers the number of employees and workers reported in the "Occupational Accident Management."

Additionally, to implement and introduce hazard prevention measures and related management regulations in accordance with national laws and regulations and the nature of different workplaces, the top supervisor establishes a safety and health organization and an Occupational Safety and Health Committee, and occupational safety and health personnel in each plant are responsible for the third-party certification (ISO 45001) inspection of the occupational safety and health management system. The certification pass rate of Taiwan plants, Wujiang Plants, and Coretronic Projection (Kunshan) is 100%. Under the ISO 45001 management system, the number of employees covered by internal audits is 15,484, the number of non-employees is 27,708, and the audit coverage ratio is 100%; the number of employees covered by external audits is 14,290, the number of non-employees is 27,022, and the audit coverage ratios are 92% and 98% respectively; Taiwan plants have also simultaneously obtained the CNS 45001 certificate. We hoped that by implementing the work plans of each management cycle, the purpose of continuous improvement can be achieved, the occurrence of occupational accidents can be reduced, and the safety and health of all employees and stakeholders can be ensured.

Occupational Safety Risk Management

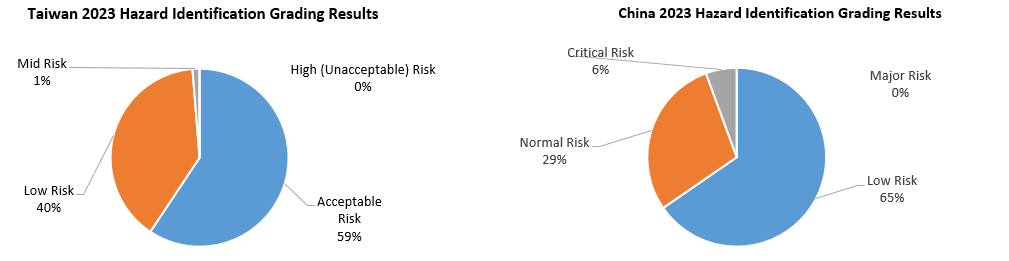

Coretronic has established hazard identification and risk assessment operation specifications, and the management unit promotes each department to regularly review and revise hazard identification and risk assessment data every year. Before changes in manufacturing process, equipment, raw materials, and working environment, hazard identification is conducted according to chemical, physical, ergonomic, biological, and other safety and health (including social and psychological) hazards, and personnel related to the implementation of hazard identification and risk assessment are required to receive at least three hours of risk assessment related training. Each department classifies different work environments, equipment or manufacturing processes, conducts job and operation inspections according to possible hazards, and cooperates with the operation process of each department to expand and fill in each operation step in the "Hazard Identification and Risk Assessment Form." Based on the severity and probability, the risk level is converted, and risk control is judged and adopted. For the higher risk hazard factors of each plant in the year, improvement plans are formulated and continuous improvement is carried out to provide employees and workers with a good work safety environment; if a major occupational accident occurs, it will be listed as a high risk level and risk control will be carried out. In 2023, Taiwan and China plants have all completed risk assessments for various operations, with no unacceptable risks or major hazards.

Referring to the local government occupational safety and health regulations in Taiwan and China, when there is an immediate danger in the workplace, the employer or the person in charge of the workplace needs to stop the operation and have employees evacuate to a safe place; if employees believe that the duties they perform have potential hazard risks, they can stop the operation and evacuate to a safe place on their own without endangering the safety of other workers, and immediately report to their direct supervisor. For employees who actively report and evacuate due to occupational safety hazard concerns, it is stated in the relevant operation specifications that they will not be punished.

Consultation, Involvement and Communication of Occupational Safety Issues

To create a comfortable and safe environment and promote communication between labor and management, Coretronic's Taiwan plants regularly hold "Occupational Safety and Health Committee" meetings, and China plants also regularly hold "Occupational Health Management Committee" and "Safety Regular Meetings." The committee members are composed of supervisors at all levels, safety and health personnel, and labor representatives. Their responsibilities are to put forward suggestions on the company's safety and health policies, and to review, coordinate, and suggest safety and health related matters. Meetings are also held quarterly to jointly decide on the planning and operation of the safety and health system, and the results are announced in paper or electronic form. All employees are encouraged to put forward occupational safety related suggestions through the "Environmental Safety and Health Zone Opinion Platform," and the management unit actively assists upon receiving notification, and the suggester will not be punished; contractors communicate occupational safety issues through the annual agreement organization meeting for advocacy, consultation, and communication.

【Items Discussed and Negotiated by Occupational Safety and Health Committee】

- Continuous promotion of a safe workplace and occupational disaster prevention

- Continuous promotion of energy saving, carbon reduction, and industrial waste reduction at plants

- Regular training to raise employees’ safety and health awareness

- Continuous rollout of ESH audit

- Management review to ensure the effective operation of the ESH management system

In 2023, Taiwan and China plants held a total of 25 Occupational Safety and Health Committee meetings and 61 contractors, and no controversial working safety cases happened in 2023.

【2023 Taiwan Occupational Safety and Health Committee】Hold the meeting quarterly, and the percentage of labor representatives in the Occupational Safety and Health Committee in Taiwan Plants are as follows:

| Taiwan Plants | Number of Labor Representatives | Number of Committee Members | Percentage of Labor Representatives |

|---|---|---|---|

| Headquarters | 6 | 13 | 46% |

| Chunan Plant | 10 | 23 | 43% |

| Tainan Plant 1 | 8 | 21 | 38% |

| Tainan Plant 2 | 3 | 9 | 33% |

| China Plants | Number of Labor Representatives | Number of Committee Members | Percentage of Labor Representatives |

|---|---|---|---|

| Kunshan Plants | 4 | 16 | 25% |

| Wujiang Plants | 6 | 18 | 33#% |

Occupational Safety and Health Training

To ensure that every employee is familiar with occupational safety and health related laws and regulations and the company's safety and health management mechanisms, environmental safety and health education and training operating procedures are formulated, and employees are provided with safety and health training courses according to laws and regulations and job requirements to enhance employees' safety and health awareness.

In 2023, Taiwan and China plants had a total of 24,115 participants in occupational safety and health education and training, with a total training time of 236,878 person-hours. On-the-job safety and health education and training includes on-the-job training for occupational safety and health business supervisors, occupational safety and health management personnel, hazardous operations supervisors, fire management personnel, Occupational Safety and Health Committee members, and general employees.

| Item / Area | Taiwan | China |

|---|---|---|

| Occupational Safety Education Training for New Employees (people) | 206 | 8621 |

| Annual Fire/Civil Defense Team Training (person-times) | 536 | 5,866 |

| Occupational Safety and Health On-the-job Training (person-times) | 1,203 | 6,570 |

| Annual Contractor Plant Entry Training (people) | 1,010 | 103 |

| Total Training Person-times (person-times) | 2,955 | 21,160 |

| Total Training Hours (person-hours) | 10,205 | 226,673 |

Disaster Response Drills

- To implement employees' disaster prevention concepts and enhance the crisis awareness and emergency response capabilities of emergency response team personnel, in addition to regularly reviewing emergency response plans, factory fire drills are also regularly conducted in cooperation with the fire department to strengthen employees' response capabilities through practical drill courses.

- In 2023, Taiwan and China plants held a total of 53 disaster response and fire drills, with a total of 7,043 participants trained and a total training time of 10,500 person-hours.

Occupational Accident Management

- To reduce the occurrence rate of occupational accidents, systematic management of occupational accident risks is conducted. In addition to formulating occupational injury and accident management operation specifications, an "Accident Report/Personnel Occupational Injury/Environmental Safety and Health Anomaly Incident Handling Record" platform is also set up to record and track the causes of accidents and corrective improvement. When various occupational injury accidents occur, hazard factors are re-examined and risks are assessed to strengthen disaster prevention. At the same time, through regular internal inspections, compliance with accident management specifications and notification system investigation mechanisms, accident analysis and improvement are implemented to ensure a safe work environment. In 2023, there were a total of 6 false alarm incidents in Taiwan plants, and only 1 occupational injury accident of tripping, excluding traffic accidents. Accident investigation analysis and individual case safety advocacy have been completed, achieving the 2023 target.

- From March 27, 2019 to December 31, 2023, an average of 299 people per month at Chunan Plant participated in the safety and health autonomous management movement promoted by the Industrial Safety and Health Association - joining the ranks of the "Zero Accident Hours Record Activity." As of the end of 2023, the cumulative zero accident hours reached 2,673,744 hours. In the future, we will continue to strive to maintain a safe work environment with the goal of "zero workplace accidents."

- In China plants, there were a total of 10 false alarm incidents, and 2 occupational injury accidents excluding traffic accidents, including 1 fall injury incident at Wujiang Plants and 1 cut injury incident at Kunshan Plants. The number of occupational injury incidents decreased by 9 compared to 2022. Accident investigation analysis and safety advocacy have been completed, achieving the 2023 target. To reduce the occurrence of occupational injury accidents, Wujiang Plants promotes safety training and advocacy for operators at stations such as production line automation equipment, assembly lines, and fixtures, increases machine warning signs, and maintains 5S in the workplace. At the same time, on-site inspection work is implemented, and the occupational injury accident occurrence rate decreased by 89% compared to 2022; Kunshan Plants continues to strengthen operator advocacy and education and training, implements on-site management and occupational accident prevention operations, and the occupational injury accident occurrence rate decreased by 50% compared to 2022.

| Area | Taiwan5 | China5 | ||

|---|---|---|---|---|

| 2023 Occupational Injury Rate | Employees4 | Workers4 | Employees4 | Workers4 |

| Total Hours Worked | 3,018,456 | 181,528 | 6,062,224 | 880,160 |

| Fatality Rate from Occupational Injuries1 | 0.0 | 0.0 | 0.0 | 0.0 |

| Numbers of Serious Occupational Injuries (excluding fatalities)2 | 1.0 | 0.0 | 2.0 | 0.0 |

| Rate of Serious Occupational Injuries (excluding fatalities)2 | 0.3 | 0.0 | 0.3 | 0.0 |

| Number of Days Lost from Disabling Injuries | 3.0 | 0.0 | 66.0 | 0.0 |

| Number of Recordable Occupational Injuries3 | 1.0 | 0.0 | 2.0 | 0.0 |

| Rate of Recordable Occupational Injuries3 | 0.3 | 0.0 | 0.3 | 0.0 |

| 1. Fatality rate from occupational injuries = Number of fatalities from occupational injuries / Working hours × 1,000,000. 2. Rate of serious occupational injuries (excluding fatalities) = Number of serious occupational injuries (excluding fatalities) /Working hours ×1,000,000; "Number of serious occupational injuries" refers to the number of people injured due to occupational accidents and medically diagnosed as having serious injuries or illnesses. 3. Rate of recordable occupational injuries = Number of recordable occupational injuries / Working hours × 1,000,000; in Taiwan plants, "Number of recordable occupational injuries " refers to the number of cases that should be reported as occupational accidents according to the announcement of the Occupational Safety Administration; in China plants, it refers to the number of cases recorded according to company regulations on human resource system data. 4. Employed employees and non-employed workers: Each Taiwan plant is calculated based on occupational accident reporting statistics from January to December 2023; China plants are calculated based. 5. Taiwan Plants include Coretronic (Lixing Plant, Chunan Plant, Tainan Plant 1, and Tainan Plant 2); China Plants include Kunshan Plants (Coretronic Projection (Kunshan), Coretronic Optics (Kunshan)) and Wujiang Plants (Coretronic Display (Suzhou), Coretronic Optotech (Suzhou), and Coretronic Optics (Suzhou)). |

||||

Contractor Management

Except for our employees, contractors are also Coretronic important partners. To ensure the health of partners, maintain facility safety, and concretely implement Coretronic commitment to workplace health and safety, Taiwan plants have clear supplier and contractor management operation specifications, and regularly conduct contractor evaluations to ensure that contractors meet the plant entry specifications; at the same time, emphasis is placed on communication and hazard notification for non-employee workers. Construction contractors participate in the "Contractor Workplace Hazard Notification and Agreement Meeting" before entering the plant, and all construction personnel need to receive Coretronic "Contractor Environmental Safety and Health Education and Training"; construction applications and management before, during, and after the project are effectively controlled by the electronic construction application system.

Through the implementation of contractor safety and health management, the Taiwan plants have had no contractor incidents for 9 consecutive years from 2015 to 2023.

The China plants have also had no contractor incidents for 2 consecutive years from 2022 to 2023.