Issue Date: January 10, 2025

Suppliers are important partners for our sustainable operations. Coretronic's Taiwan/China plants have a total of 1,520 qualified suppliers (including 1,339 domestic suppliers, accounting for 88%, and 181 overseas suppliers). We classify and manage suppliers based on their characteristics and the goods and services they provide and prioritize local procurement as a strategy to promote local economic development, ensure stable operations, accelerate production efficiency, and minimize carbon emissions during transportation as much as possible.

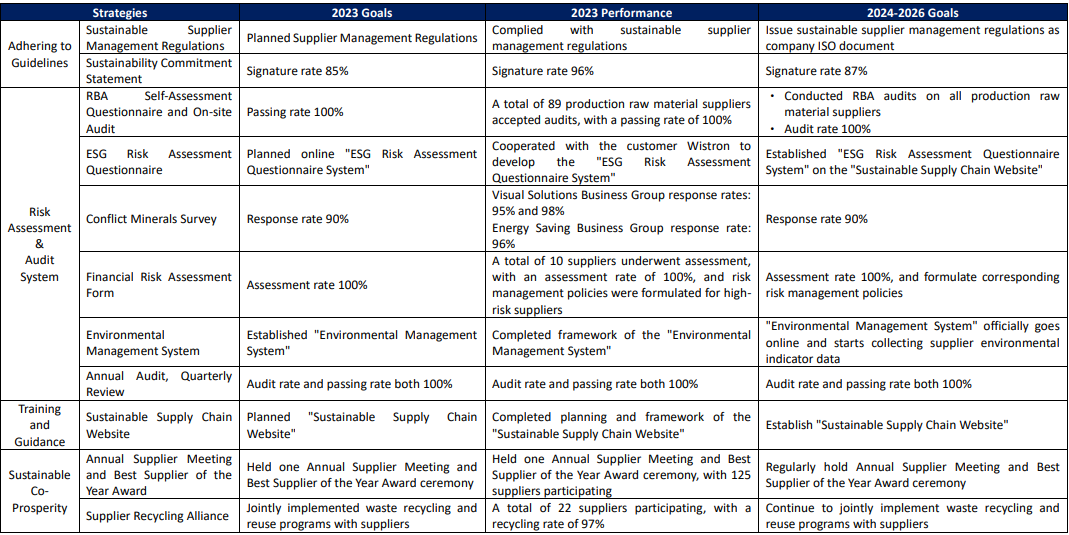

To work hand in hand with supplier partners to achieve the vision of "sustainable co-prosperity", we have established the "Sustainable Supplier Management Regulations" for production raw material suppliers, including requiring supplier partners to comply with standards, conducting risk assessments, audits, training and guidance, and using the Annual Supplier Meeting to commend outstanding suppliers and share sustainable trend topics to ensure that supplier partners can operate sustainably. In addition, we have formulated the "Responsible Business Alliance Code of Conduct Management Handbook" based on the Responsible Business Alliance (hereinafter referred to as RBA) to manage suppliers, striving to urge suppliers to pay attention to issues such as ethics, labor human rights, environmental protection, health and safety, thoroughly implement risk management and business continuity plans, in order to establish a sustainable supply chain. If supplier partners have any sustainability-related suggestions, they can make proposals and inquiries through mail to: CSR@coretroic.com

Sustainable Suppliers Code of Conduct

Adhering to Guidelines

Sustainability Commitment Statement

To effectively implement the sustainable supply chain management strategy, relevant management measures were established in 2021, and based on RBA, the "Sustainability CommitmentStatement" was formulated, requiring all production raw material suppliers to sign (except for customer-designated suppliers, affiliated companies, and suppliers that have obtained exemption from signing due to already having public sustainability information/reports/certificates), to ensure that suppliers can comply with RBA 7.0, Green Product Warranty (promise and guarantee that the products meet the "Green Product Procurement Specifications", and provide RoHS test laboratory test reports from third-party certification bodies, environmental hazardous substance questionnaires, lead-free component reliability questionnaires, safety data sheets (SDS), material certificates, and test summary forms), Responsible Minerals Procurement Policy, Declaration on Non-Use of Conflict Minerals, Integrity Commitment, and Environmental Sustainability and Occupational Safety and Health Policy. In 2023, a total of 530 suppliers were required to sign the "Sustainability Commitment Statement", and 510 suppliers have signed, with a signing rate of 96%.

Conflict Minerals Management

We regard conflict minerals as key raw materials and manage them accordingly. We do not accept illegally mined gold, tantalum, tin, tungsten, cobalt and mica from the Democratic Republic of the Congo and neighboring conflict regions. Therefore, we have formulated the "Responsible Minerals Procurement Policy" and "Declaration on Non-Use of Conflict Minerals" according to RBA and added them to the "Sustainability Commitment Statement", and announced the conflict minerals control requirements to suppliers at the Annual Supplier Meeting. All production raw material suppliers must sign the "Sustainability Commitment Statement" to ensure that they can comply with conflict minerals-related regulations. The relevant policies and survey results are also published on the Company's official website.

RBA VAP

Both Coretronic Projection (Kunshan) and Coretronic Optics (Suzhou) independently applied for RBA VAP in 2023, and were rated 166.1 points and 163.8 points respectively, both reaching the silver standard, fully demonstrating green enterprise leadership

Risk Assessment

- RBA Self-Assessment Questionnaire: To effectively assess the various sustainability risks of production raw material suppliers, we send RBA self-assessment questionnaires to all suppliers that need to undergo RBA audits, allowing suppliers to self-assess their sustainability implementation status, and conduct RBA on-site audits after they respond to the self-assessment questionnaire.

- ESG Risk Assessment Questionnaire: To better understand suppliers' sustainable development status and facilitate subsequent guidance for suppliers to become members of the sustainable supply chain, while meeting the requirements of important customers, foreign investors, international ratings and sustainability norms, since 2022, we have successively negotiated with third-party verification units and important customers, hoping to conduct supplier sustainability risk assessment and surveys in a more efficient, comprehensive and credible manner. At the end of 2023, it was decided to cooperate with the customer Wistron on the "ESG Risk Assessment Questionnaire" system. Through the AI preliminary review mechanism, 60% of manpower and document review time can be

reduced, while maintaining the consistency of review standards. It is expected to be built on the "Sustainable Supply Chain Website" in the first half of 2024, allowing suppliers to fill out questionnaires online, and then identify suppliers' awareness and management level of sustainability management based on the self-assessment results, and conduct sustainability risk classification, in order to plan appropriate improvement measures for suppliers. - Conflict Minerals Survey

- Visual Solutions Business Group: Used RMI CMRT 6.31 and EMRT 1.2 versions of the conflict minerals survey to conduct a more detailed conflict minerals survey on all production raw material suppliers, with response rates of 95% and 98% respectively. In the future, the survey recipients will be re-evaluated, considering excluding customer-designated suppliers and suppliers that have publicly declared compliance with conflict minerals regulations, and guiding suppliers that do not meet the requirements to make improvements to increase the response rate.

- Energy-Saving Business Group: Using RMI CMRT 6.31 and EMRT 1.2 versions of the Conflict Minerals Survey, we surveyed all productive electronic raw material suppliers, with a 96% response rate. - Financial Risk Assessment Questionnaire: Starting from 2020, the Procurement Department annually submits the list of suppliers with potential risks approved by the business group supervisors to the Finance Department for annual supplier financial risk assessment. The Finance Department will conduct risk classification based on the supplier's public financial data, financial statements, and reports obtained from third-party credit agencies (such as Dun & Bradstreet or credit insurance company cooperating credit report vendors), and submit the final results to the CFO for approval. The Procurement Department will then remove high-risk suppliers based on the results. In 2023, a total of 10 suppliers underwent financial risk assessment. According to the assessment results, 4 suppliers were high risk, 4 suppliers were medium risk, and 2 suppliers were low risk. For high-risk suppliers, in addition to formulating more stringent risk management measures and requiring them to improve as soon as possible, alternative suppliers are also actively sought to reduce potential risks. For low and medium risk suppliers, risk management policies have been formulated and require them to

improve as soon as possible. Among the 4 suppliers that underwent financial risk assessment in 2022, 1 supplier was still listed as high risk in 2023. The Procurement Department has reduced the 5 order allocation ratio of the supplier and continues to track the subsequent situation. The other 3 were confirmed to have no risk of material shortage and recourse after judgment, so they were removed from the 2023 supplier risk list.

Training

Green Product Management System (GPMS)

This platform includes Announcement Area, MCD Request Area (Material Composition Declaration Request, material declaration area), and Supplier List Area. The announcement area on the homepage provides information such as new versions of green product specifications and GPMS platform training videos to avoid suppliers following incorrect regulatory content or using incorrect forms. It also provides the functions of inquiry for purchasers/engineers to check the status of supplier document uploads, maintain the contact list of raw material suppliers, for suppliers to fill in RoHS 2.0, SVHC, SDS information, and for administrators to download reports based on the model BOM table.

Sustainable Supply Chain Website

To raise the sustainability awareness of supplier partners, we guide them to become members of the sustainable supply chain, and integrate all platforms related to supplier management, in 2023, the content and framework planning of the "Sustainable Supply Chain Website" was completed, including seven major functions: sustainability standards (Sustainability Commitment Statement, Sustainable Supply Chain Management Regulations), sustainability risk investigation (conflict minerals, financial risks, ESG risks, environmental data), sustainability online courses, sustainability activities (Annual Supplier Meeting, Annual Best Supplier, Earth Day activities), GPMS, material carbon footprint database, online consultation, etc. It is expected to be established from 2024 to 2026.

Green Alliance

Annual Supplier Meeting

Since 2017, we have been promoting responsible supply chain and working with suppliers to make progress in aspects of quality, cost, delivery, environmental protection, safety and health. At the same time, through on-site guidance and face-to-face communication, we enhance supply chain management capabilities to fulfill sustainable commitments. To continue strengthening supply chain resilience and improving adaptability.

The 2023 annual supplier meeting focused on sustainable trends and shared with supplier partners the Company's sustainable development management results, sustainable supply chain management strategies, green manufacturing and product concepts, and future sustainable development plans. We will continue to work hand in hand with supplier partners to achieve a win-win supply chain relationship, while calling on supplier partners to pay attention to climate change issues and invest more in environmentally friendly actions to jointly create a sustainable supply chain.

Best Supplier of the Year Award

During the annual supplier meeting, we recognize supplier partners with outstanding energy-saving and carbon-reduction performance and sustainability performance through awards. In 2023, we awarded the "Energy Saving and Carbon Reduction Contribution Award" and the "Sustainability Award" to 16 outstanding suppliers. The "Energy Saving and Carbon Reduction Contribution Award" refers to suppliers who have continuously cooperated in packaging material recycling and circular use of carriers (trolleys) during the transaction period and jointly promoted specific carbon reduction effects on the environment during the transaction period. The "Sustainability Award" is given to suppliers whose supply performance and response capabilities have helped improve the resilience of the supply chain system within a specified time.

Supplier Recycling Alliance

We jointly promote waste recycling and reuse programs with suppliers, implementing packaging material recycling plans for plastics, paper, etc. In addition to recycling packaging materials, we also use reusable packaging for shipment and recycling to reduce the consumption of raw materials for production packaging or carriers, while also advocating the concept of circular reuse and waste reduction, which is more environmentally friendly. In 2023, a total of 22 suppliers responded to the recycling of acrylic protective boards, cartons, pallets, wooden pallets, plastic boxes, trolleys, plastic and foam protective materials, with a recycling rate of 97%.

External CDP's Recognition of Partnership

External CDP's Recognition of PartnershipIn the 2023 CDP Supplier Engagement Rating, Coretronic went a step further and obtained the highest rating of A (Leadership Level), surpassing the industry, Asia and global average (C). We are committed to supplier partnerships and actively engage in value chain partner engagement for climate change mitigation and adaptation. The rating items are "Supplier Engagement", "Targets", "Scope 3 Emissions", "Overall CDP Climate Change Score" and "Governance" in five aspects. We obtained the highest rating of A (Leadership Level) in three items: "Supplier Engagement", "Targets" and "Scope 3 Emissions". In the future, we will continue to invest in value chain management and work with suppliers and customers to demonstrate the best performance in operational resilience.

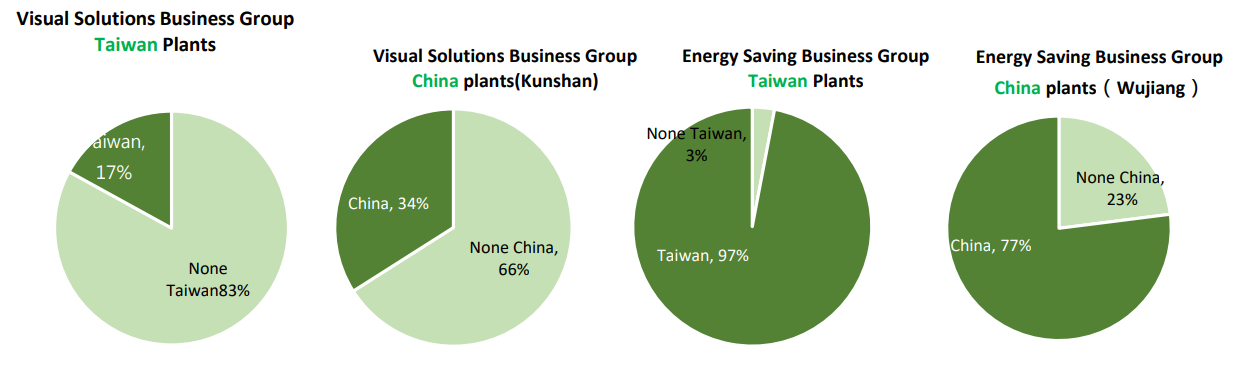

Local Procurement

We understand the impact of the environmental footprint on the environment during the process of purchasing raw materials and components, so localization of procurement is an important strategy for finding supplier partners. We also expect supplier partners to operate as much as possible through localized procurement, working together to do their part for environmental protection. Please refer to the figure below for the proportion of procurement amount in 2023. Among them, the Energy Saving Business Group's Taiwan plants actively implement the local procurement strategy, with a proportion as high as 97%, while the Visual Solutions Business Group's Taiwan and China plants (Kunshan), due to the need to purchase key components from specific foreign suppliers to maintain product quality, the proportion of local procurement is lower, but for the procurement of other components, it will still strive for localized procurement.