Issue Date: September 17, 2025

Energy Management

Energy Management Strategies

Upholding the duty as a corporate citizen, we spare no effort to implement environmental and social responsibilities while operating the company and developing technology. Therefore, we established the Energy Management System Promotion Committee in 2016 to actively promote the continual improvement plans and activities of various energy conservation measures. In addition, to implementing an energy management system meeting international standards, we have established an energy management policy and made the following commitments:

- Continuously improve energy performance and reduce energy consumption costs.

- Implement the energy management system and reduce GHG emissions.

- Abide by energy regulations and prioritize procurements of energy-efficient products.

- Improve the green corporate image and promote eco-design and green production.

- Secure acquisition of information and resources to achieve energy and resources targets.

Energy Management System

- The Chairman signed the “RE100 and EV100 Statement”, committing to the goals of achieving 100% electrification of transportation vehicles by 2030 and 100% renewable energy usage by 2040.

- Implemented an energy-saving project for the chilled water HVAC systems to improve the energy efficiency of the air conditioning system

- Installed solar power generation systems to increase the use of renewable energy

- Proposed and implemented various electricity-saving measures annually, including lighting and equipment upgrades, and optimization of operational processes

- To support the continuous implementation and certification of the ISO 50001 while enhancing the Company’s energy efficiency, internal auditors for ISO 50001 and energy-saving-related training courses were arranged for employees and contractors. A total of 153 participations with 671 training hours. Chunan Plant has passed ISO 50001 certification for 9 consecutive years; Headquarters, Tainan Plant 1, and Tainan Plant 2 have been certified for 3 consecutive years; Coretronic Optotech (Suzhou), Coretronic Optics (Suzhou), and Coretronic Projection (Kunshan) have been certified for 2 consecutive years.

- Chunan Plant improved energy efficiency through its management system, selected eco-friendly and recyclable materials, and established an indoor air quality monitoring system to enhance workplace environmental quality. In March 2024, it received the LEED Gold Certification (LEED v4.1 for Operations and Maintenance) from the U.S. Green Building Council (USGBC)—marking Coretronic’s first plant to receive an international green building certification.

Energy Usage Overview

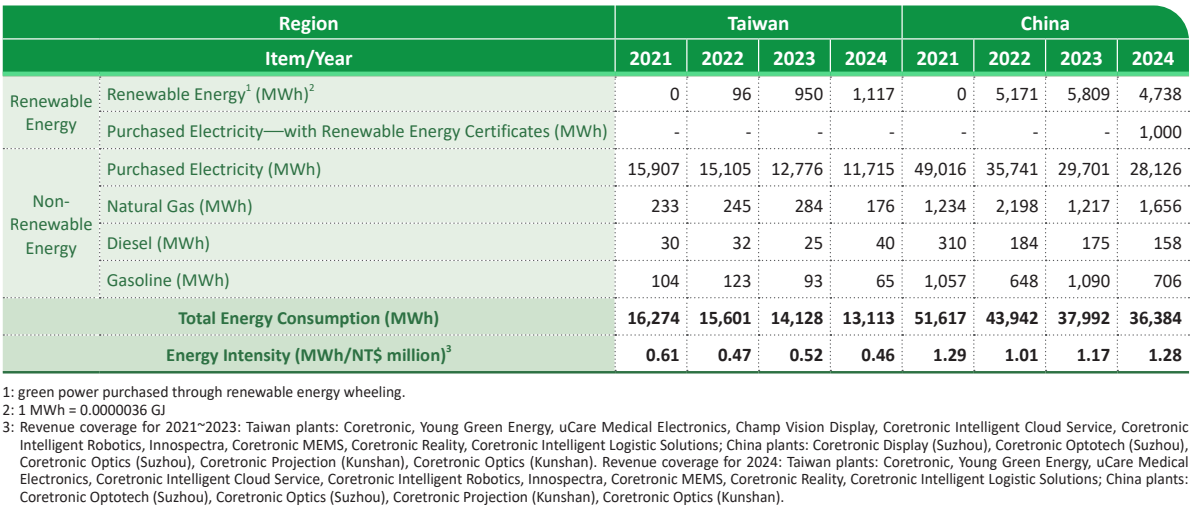

To reduce energy consumption, Coretronic has implemented the ISO 50001 Energy Management System, carried out energy-saving projects for chill water of air conditioning systems, upgraded lighting and related equipment, optimized operational processes, adopted recycled materials, and developed low-carbon products. In addition, the Company has actively promoted the development of renewable energy to increase its usage ratio. In 2024, total energy consumption was 49,497 MWh, representing a 5% reduction compared to 2023 and a 27% reduction compared to the 2021 baseline year. Taiwan plants reached 7% reduction compared to 2023 and 19% reduction compared to the 2021 baseline year. China plants reached 4% reduction compared to 2023 and 30% reduction compared to the 2021 baseline year.

Renewable Energy

- Commitments and Targets

- 2025: 15% of renewable energy in annual electricity consumption

- 2026~2028: 21% of renewable energy in annual electricity consumption

- 2029~2031: 27% of renewable energy in annual electricity consumption

- 2040: 100% of renewable energy in annual electricity consumption - Strategies

- 2016~2017: Purchased green electricity

- 2018: Installed a solar power generation system at Tainan Plant 1

- 2020: Set renewable energy targets

- 2021: Installed solar power generation systems for Coretronic Display (Suzhou), Coretronic Optotech (Suzhou), and Coretronic Optics (Suzhou) with installed capacities of 1,207.8, 4,068.9, and 653.4 kW respectively

- 2022: Installed a solar power generation system for Coretronic Projection (Kunshan) and Coretronic Optics (Kunshan) with an installed capacity of 618.9 kW; Taiwan plants began purchasing renewable energy certificates and sourcing green power via renewable energy wheeling

- 2023: Installed solar power generation systems for Chunan Plant, Tainan Plant 1, and Tainan Plant 2 with installed capacities of 367.41, 317.46, and 132.44 kW respectively

- 2024: Installed a solar power generation system for the Headquarters with an installed capacity of 98.4 kW - 2024 Results

- The Headquarters completed the installation of a 98.4 kW solar power generation system, which will begin generating electricity in 2025.

- Through a combination of self-generated solar power, green power purchased via renewable energy wheeling, and renewable energy certificates, total renewable energy usage reached 6,855 MWh, achieving a carbon reduction of 3,631 metric tons. Renewable energy accounted for 15% of total annual electricity consumption.

- The Chairman signed the “RE100 and EV100 Statement”, pledging to achieve 100% electrification of transportation vehicles by 2030 and 100% renewable energy usage by 2040.

2: China plants’ emission factor used is 0.5366 tCO2e/MWh, which is the 2024 national grid average emission factor in China.

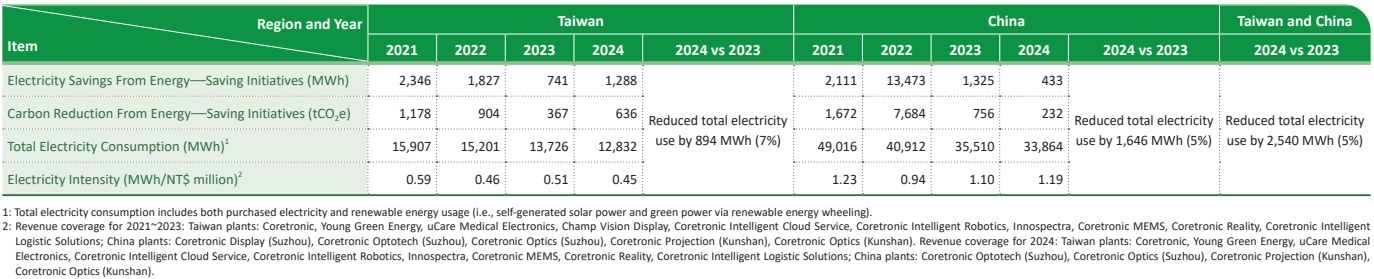

Energy-Saving Measures and Performance

From 2015 to 2024, Coretronic implemented 389 energy-saving projects across Taiwan and China plants, reducing electricity consumption by 31,933 MWh and cutting carbon emissions by nearly 18,000 metric tons of CO₂e, equivalent to the annual carbon absorption of 48 Da’an Forest Parks. Going forward, the Company will continue to strengthen its energy management efforts to further improve efficiency, reduce carbon emissions, and move toward its carbon neutrality goals.

- In 2024, Coretronic carried out 30 energy-saving initiatives, reducing electricity consumption by 1,721 MWh and 868 metric tons of CO₂e.

- Total electricity consumption in 2024 was 46,696 MWh, a 5% reduction compared to 2023. Electricity intensity decreased by 15% compared to the 2021 baseline year, achieving the short-term target.