Issue Date: September 24, 2025

Waste Management

Coretronic’s waste generated from operating activities is mainly non-hazardous waste. However, other flammable mixtures and electronic components arising from research and experimental processes are classified as hazardous industrial waste, which are incinerated and physically treated. The Company manages hazardous industrial waste through the control and categorization of scrap materials to reduce the generation of hazardous industrial waste. The Company also requires suppliers to implement waste flow control measures jointly, thus fulfilling the environmentally friendly commitment.

Taiwan plants, Wujiang plants, and Coretronic Projection (Kunshan)* have introduced and obtained ISO 14001 Environmental Management System certification. Through the lens of a product's life cycle, Coretronic examines the detailed processes of waste generation, removal, treatment, and recycling at different stages, implementing waste reduction strategies through system management and formulates an audit plan to prevent unlawful activities or environmental risks resulting from improper handling.

* Coretronic Optics (Kunshan) is an upstream supplier of Coretronic Projection (Kunshan), and its environmental management system is jointly managed with Coretronic Projection (Kunshan). It is expected to obtain ISO 14001 certification in the future in response to customer requirements.

Waste Management Strategies

- Establish and publicly announce a “Plastic Reduction Commitment”, encouraging all employees to sign the pledge

- Strengthen waste management and increase the recycling rate

- Design volume-reducing and material-saving products to minimize waste generation

- Prioritize the use of recycled materials to reduce waste and promote circular utilization

- Raise employees' waste reduction awareness

- Commission licensed contractors for proper waste disposal

Waste Generation Status

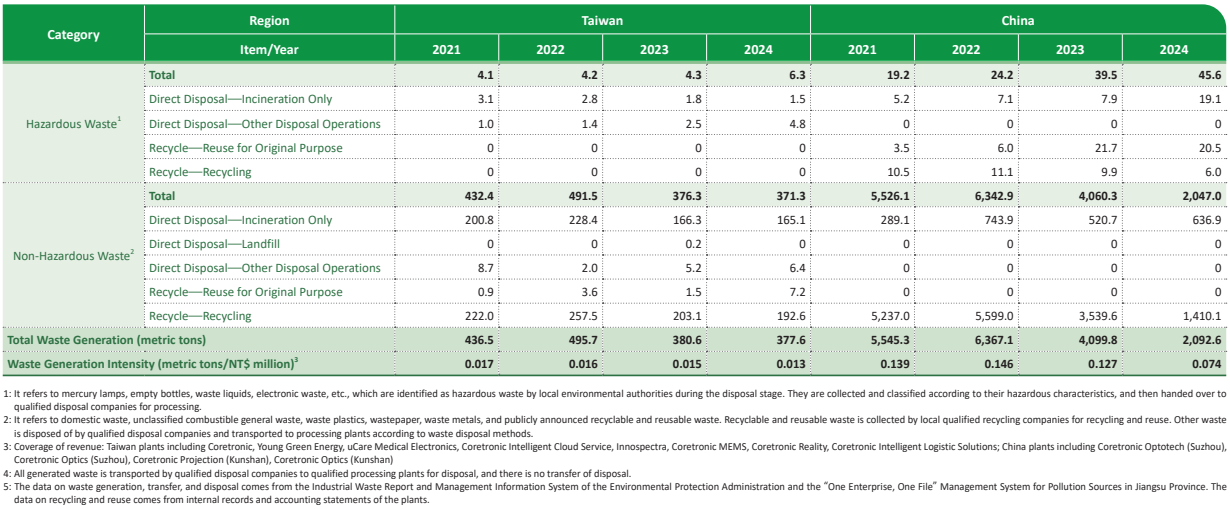

The company categorizes waste based on its environmental impact into hazardous and non-hazardous waste. Non-hazardous waste is further divided into domestic waste, recyclable waste, recyclable waste, and general waste, and is managed under five categories based on disposal methods. Except for domestic and recyclable waste, all other waste originates from the manufacturing process. In 2024, the Taiwan plants produced 377.6 metric tons of waste, of which hazardous directly disposed waste accounted for 2%, non-hazardous directly disposed waste accounted for 45%, and non-hazardous recycled waste accounted for 53%. China plants produced 2,092.6 metric tons of waste, of which hazardous directly disposed waste accounted for 0.9%, non-hazardous directly disposed waste accounted for 30.4%, and non-hazardous recycled waste accounted for 67.4%.

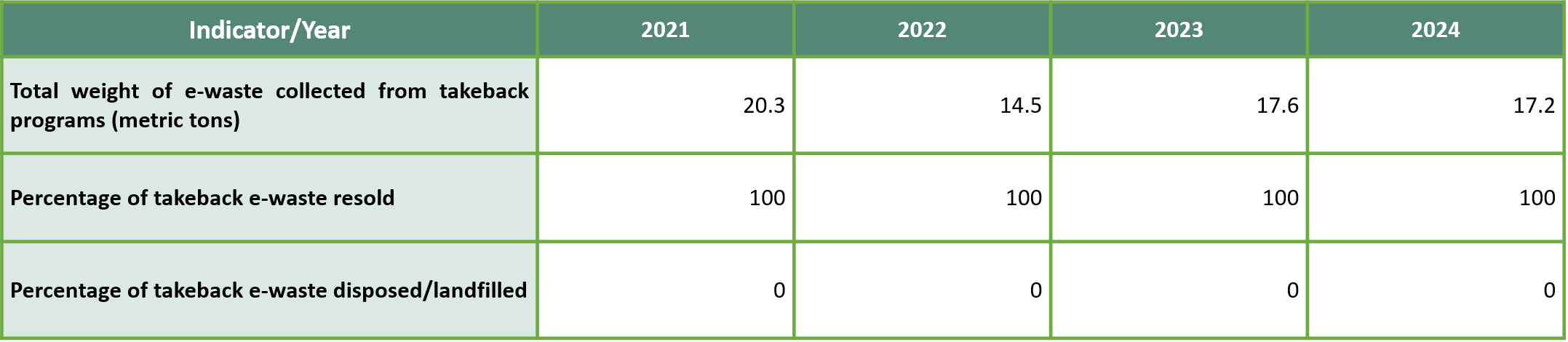

The Status of the Take-Back Programs of E-Waste

Waste Reduction Strategies

- Reuse of Packaging Materials

In 2024, Coretronic implemented 6 packaging material recycling initiatives, achieving an overall recovery rate of 96%. The recycling results were counted by pieces, with 97% for trays, 76% for pallets, 67% for plastic pads, and 95% for paper boxes. In total, 805 metric tons of reusable packaging materials were recovered, resulting in a reduction of 1,658 tCO₂e and cost savings of NT$210,000 in pallet purchasing and waste disposal fees. (According to the Low Carbon Sustainable Information System website, each metric ton of waste generates 2.06 tCO₂e.) - Circular Economy Alliance

- Pallet reuse: Since 2017, Coretronic has partnered with local logistics suppliers for 8 consecutive years to recover and reuse original pallets for transportation. From 2017 to 2024, a total of 494.6 metric tons of pallets were recovered, reducing 1,019 tCO₂e and saving NT$2.26 million in pallet purchase and waste disposal costs.

- Tray recycling and reprocessing: Tainan Plant 1 has recycled defective trays, which were reprocessed for reuse. From 2021 to 2024, 1.8 metric tons of trays were recovered, reducing 3.7 tCO₂e. - Lightweight Chemical Containers

Since 2022, the Kunshan plants have replaced 500 mL glass ethanol containers with 2.5 L plastic bottles. Each liter of ethanol used results in a 0.768 kg reduction of hazardous industrial waste. From 2022 to 2024, this initiative reduced 4.5 metric tons of waste and 1.4 tCO₂e and saved RMB 17,580 (approximately NT$77,000) in waste disposal fees. (According to the Carbon Footprint Information Platform website, each metric ton of hazardous industrial waste disposed of by landfill generates 0.3 tCO₂e.) - End-of-Life Product Tracking

To ensure that reused products are handled legally, Coretronic has established clear waste management operating procedures and conducts annual on-site audits of waste disposal companies' compliance with regulations and their downstream processing capabilities. If non-compliance is found, guidance and follow-up improvements are provided, and if the issues persist, the disposal contract will be terminated to ensure proper and legal waste disposal. In 2024, Coretronic audited 40 waste disposal companies, covering general, recyclable, and hazardous waste, with a 100% audit completion rate and no irregularities found.