Issue Date: July 18, 2025

Supply Chain Management

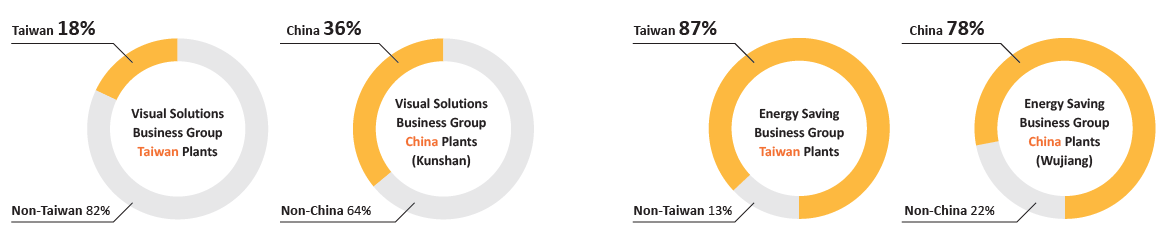

Suppliers are key partners in the Company’s sustainable operations. Coretronic has a total of 1,296 qualified suppliers across its Taiwan and China plants, including 1,124 domestic suppliers ( accounting for 87%) and 172 overseas suppliers. The Company manages suppliers by categorizing them according to their characteristics and the products or services they provide. Its strategy prioritizes local procurement to promote local economic development, ensure operational stability, accelerate production efficiency, and minimize carbon emissions generated during transportation.

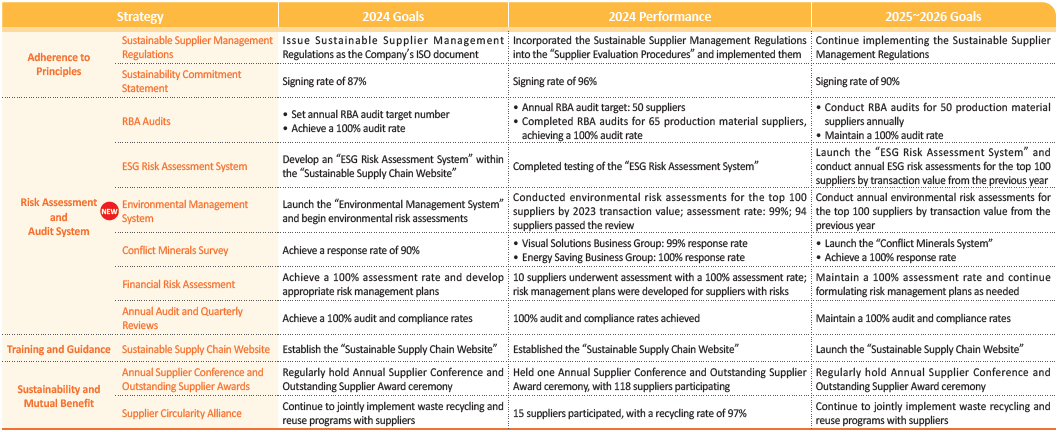

To achieve the vision of “sustainability and mutual benefit” with its supplier partners, Coretronic has established the “Sustainable Supplier Management Regulations” for production materials suppliers. These regulations include requiring supplier partners to adhere to the principles, conducting supplier risk assessments, audits, training and guidance, and recognizing outstanding suppliers while sharing sustainability trends during the Annual Supplier Conference. These efforts aim to ensure that its supplier partners can operate sustainably. In addition, the Company manages suppliers in accordance with the Responsible Business Alliance (RBA) Code of Conduct. The Company strives to encourage suppliers to give due attention to ethics, labor and human rights, environmental protection, health and safety, and to thoroughly implement risk management and business continuity plans to build a sustainable supply chain. If supplier partners have any suggestions or inquiries related to sustainability, they may contact us via ESG@coretronic.com.

Sustainable Supplier Management Regulations

Adherence to Principles

- Sustainability Commitment Statement

To effectively implement the sustainable supply chain management strategy, relevant management measures were established in 2021, and based on RBA, the “Sustainability Commitment Statement” was formulated, requiring all production material suppliers to sign (except for customer-designated suppliers, affiliated companies, and suppliers that have obtained exemption from signing due to already having public sustainability information/reports/certificates), to ensure that suppliers can comply with the “RBA Code of Conduct”, “Green Product Warranty (promise and guarantee that the products meet the “Green Product Procurement Specifications”, and provide RoHS test laboratory testing reports from third-party certification bodies, environmental hazardous substance questionnaires, lead-free component reliability questionnaires, safety data sheets (SDS), material certificates, and test summary forms), “Conflict Minerals Policy”, “Conflict Minerals Declaration”, “Integrity Commitment”, and “Environmental Sustainability and Occupational Safety and Health Policy”. In 2024, a total of 444 suppliers were required to sign the “Sustainability Commitment Statement”, and 427 suppliers have signed, with a signing rate of 96%. Additionally, in response to the release of RBA 8.0 and updates to complaint hotlines at certain plants, the content of the “Sustainability Commitment Statement” was revised, including updates to the “RBA Code of Conduct”, “Conflict Minerals Policy”, “Conflict Minerals Declaration”, and “Integrity Commitment”. In line with the SA8000 implementation plan, a new “Human Rights and Social Responsibilities Policy” will be added to the “Sustainability Commitment Statement” in 2025 and distributed to all applicable production material suppliers via the “ESG Risk Assessment System” for signing. - Conflict Minerals Management

Coretronic regards conflict minerals as key raw materials and manages them accordingly. The Company does not accept minerals from conflict-affected and high-risk areas, as defined by the OECD (Organisation for Economic Co-operation and Development) or other recognized organizations, including, but not limited to, gold, tantalum, tungsten, tin, cobalt, and mica. Therefore, by the end of 2024, the Company revised the “Conflict Minerals Policy” and “Conflict Minerals Declaration” in line with RBA 8.0 and updated them in the “Sustainability Commitment Statement”. During the Annual Supplier Conference, the Company communicated its conflict mineral control requirements to suppliers. All production material suppliers are required to sign the “Sustainability Commitment Statement” to ensure compliance. Relevant policies and survey results are also published on the Company’s official website. - RBA VAP

Coretronic Projection (Kunshan) and Coretronic Optics (Suzhou) voluntarily applied for the RBA Validated Assessment Program (VAP) in 2023, earning 166.1 points and 163.8 points, respectively. Both were awarded Silver-Level Certificates.

Risk Assessment

- RBA Self-Assessment Questionnaire: To effectively assess the various sustainability risks associated with production material suppliers, the Company sends RBA self-assessment questionnaires to all suppliers that require RBA audits, allowing suppliers to self-assess their sustainability implementation status, and conduct RBA on-site audits after responding to the self-assessment questionnaire.

- ESG Risk Assessment System: To better understand suppliers’ sustainability performance and assist them in becoming part of a responsible supply chain, and to meet the expectations of key customers, domestic and foreign institutional investors, international ratings, and sustainability regulations, the Company began developing an “ESG Risk Assessment System” at the end of 2023. The system incorporates an AI-based preliminary review mechanism, which reduces manual workload and document review time by 60% while maintaining consistent auditing standards. The platform was completed and tested in 2024 and is scheduled for official launch in 2025. In the third quarter of each year, the top 100 production material suppliers (by transaction value from the previous year) will be required to complete the questionnaire through the system. Based on the assessment results, the Company will evaluate the suppliers’ sustainability awareness and management capabilities, classify their sustainability risks, and develop tailored improvement measures for each supplier.

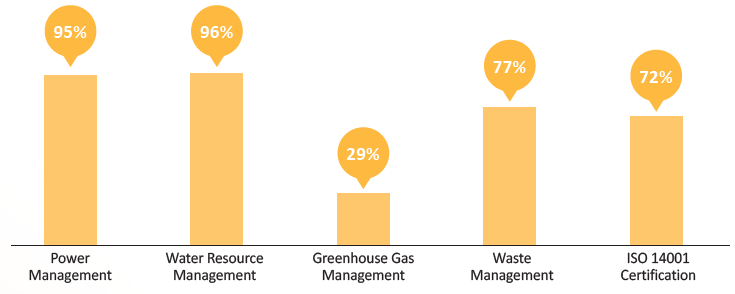

- Environmental Management System: To progressively fulfill the Company’s Net Zero Commitment, a supply chain carbon reduction program was initiated in 2023 alongside the development of an Environmental Management System. The system was fully built and officially launched in 2024. The top 100 suppliers by transaction value in 2023 were invited and guided to submit environmental indicator data through the system to enable environmental risk assessments. In 2024, a total of 98 suppliers were assessed (originally 101, but 3 suppliers confirmed to cease transactions in the future), and 97 responded, resulting in a 99% response rate. Of these, 94 suppliers passed the review and received guidance; 93 suppliers have implemented electricity management, and 28 suppliers have adopted greenhouse gas management practices. Going forward, suppliers will be supported in setting renewable energy usage rates and carbon reduction targets to achieve net-zero emissions gradually. Their carbon reduction performance will be incorporated into the evaluation of sustainability practices and considered as an important factor in future investment decisions.

- Conflict Minerals Survey:

- Visual Solutions Business Group: Conduct a detailed conflict minerals survey for all production material suppliers using RMI CMRT 6.4 and EMRT 1.3 versions of the survey. The response rate reached 99%.

Energy Saving Business Group: Conduct a conflict minerals survey for all production-related electronic material suppliers using RMI CMRT 6.31, CMRT 6.4, EMRT 1.2, and EMRT 1.3 versions of the survey. The response rate reached 100%. - Financial Risk Assessment Questionnaire: Since 2020, the Procurement Department has annually provided a list of suppliers with potential risks (approved by business group senior executives) to the Finance Department for financial risk assessment. The Finance Department classifies supplier risk levels based on their public financial data, financial statements, and third-party credit reports (e.g., from Dun & Bradstreet or insurers’ partnered credit agencies). The results are then submitted to the Procurement Department for final decisions. In 2024, a total of 10 suppliers underwent financial risk assessment: 2 suppliers were identified as high risk, 5 as medium risk, and 3 as low risk. Among the 2 high-risk suppliers, 1 is a single-source supplier and a globally renowned company; the Procurement Department will continue to monitor. The other is currently an active supplier; the Procurement Department will continue to monitor delivery performance and temporarily suspend new project collaborations. For the low- and medium-risk suppliers, appropriate risk management strategies have been formulated.

Audit System

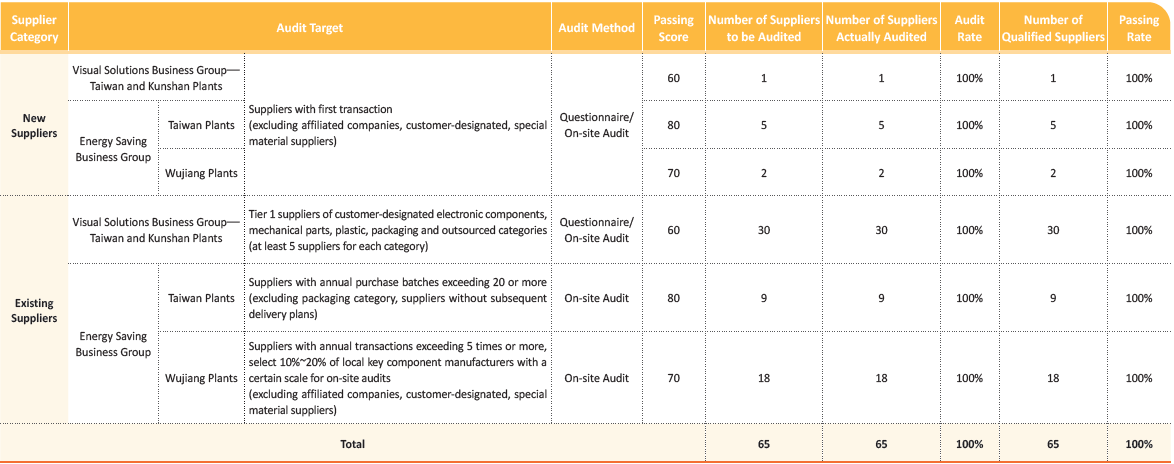

- RBA Audit

In 2024, the Company set an annual target for RBA audits, requiring that 50 production material suppliers must be audited each year with a 100% audit rate. For suppliers who fail to meet standards, the Company will provide guidance to help them improve within a specified period. After submitting a corrective action report, the responsible unit will conduct a re-evaluation. In 2024, 65 production material suppliers (including 8 new suppliers) underwent RBA audits. All 65 suppliers passed, achieving both a 100% audit rate and a 100% passing rate.

The Company incorporates the RBA audit into its supplier ESG risk assessment. For new suppliers of the Visual Solutions Business Group, procurement staff are required to record the RBA audit score in the “New Supplier Evaluation Form”, with the score weighted at 10% of the overall supplier evaluation. For new suppliers of the Energy Saving Business Group and all existing suppliers, the RBA audit score is assessed as an independent measure.

Training and Guidance

- Green Product Management System (GPMS)

This platform includes an announcement section, a Material Composition Declaration (MCD) Request section, and a supplier list section. The announcement section on the homepage provides updates such as the latest green product specifications and GPMS training videos to prevent suppliers from following outdated regulations or using incorrect forms. It also allows procurement/engineers to check the status of supplier document uploads and maintain the contact list of raw material suppliers. Suppliers can fill in RoHS 2.0, SVHC, and SDS information, while administrators can download reports based on the model BOM table. - Sustainable Supply Chain Website

To raise supplier awareness of sustainability and guide them to become part of a sustainable supply chain, Coretronic integrated all supplier-related management platforms and completed the structure and content design of the “Sustainable Supply Chain Website” in 2023. The website includes seven major functions: sustainability principles (platform for signing the Sustainability Commitment Statement, Sustainable Supply Chain Management Regulations), sustainability risk assessments (Conflict Minerals System, Financial Risk Assessment Questionnaire, ESG Risk Assessment System, Environmental Management System), sustainability online courses, sustainability events (Annual Supplier Conference, Outstanding Supplier Awards, Earth Day activities), GPMS, material carbon footprint database, and online consultation. In 2024, the “Environmental Management System” was officially launched. The “Conflict Minerals System”, “Sustainability Commitment Statement Signing Platform”, and “ESG Risk Assessment System” are scheduled to launch in 2025, while the remaining platform functions are expected to be completed by 2026.

Sustainability and Mutual Benefit

- Annual Supplier Conference

Since 2017, Coretronic has been promoting a responsible supply chain by working closely with suppliers to improve across key areas such as quality, cost, delivery, environmental protection, safety, and health. Through on-site guidance and face-to-face communication, the Company continues to enhance supply chain management capabilities and fulfill its sustainability commitments. To further strengthen supply chain resilience and improve adaptability, the Company remains focused on building sustainable partnerships.

The 2024 Annual Supplier Conference continued to center on sustainability trends. In addition to sharing the Company’s sustainability management achievements, sustainable supply chain strategies, green manufacturing and product concepts, and future sustainability plans with suppliers, Coretronic officially announced the launch of its “Environmental Management System”. Suppliers were invited to submit environmental indicator data through the system to support its environmental risk assessments and help us design tailored guidance programs. The Company will continue to work hand-in-hand with its supplier partners to foster a collaborative and sustainable supply chain relationship, together advancing a shared vision of sustainability. - Outstanding Supplier Awards

Through the Annual Supplier Conference, Coretronic recognizes and rewards supplier partners who have demonstrated excellence in carbon reduction and sustainability performance. In 2024, a total of 52 outstanding suppliers were honored with the “Energy Saving and Carbon Reduction Contribution Award”, the “Outstanding Supplier Sustainability Award”, the “Outstanding Supplier Model Award”, and the “Outstanding Supplier Performance Award”—an increase of 36 awardees compared to the previous year. The Company aims to encourage broader participation in sustainability efforts through tangible incentives and public recognition. - The “Energy Saving and Carbon Reduction Contribution Award” honors suppliers that have successfully reduced energy consumption and carbon emissions. The “Outstanding Supplier Sustainability Award” recognizes suppliers committed to environmental protection and social responsibility. The “Outstanding Supplier Model Award” highlights benchmark suppliers with outstanding overall performance aligned with the principles of R.I.S.E (Responsibility, Innovation, Safety, Excellence).The “Outstanding Supplier Performance Award” is given to suppliers who excel in technical innovation, process optimization, and overall collaboration.

- Supplier Circularity Alliance

Coretronic collaborates with suppliers to promote waste recycling and reuse programs, implementing recycling plans for packaging materials such as plastics and paper. In addition to packaging material recycling, the Company also adopts reusable packaging for material delivery and collection, which reduces the consumption of raw materials used in packaging or containers. This practice promotes the concept of circular economy by encouraging reuse and waste reduction, contributing to a more environmentally friendly operation. In 2024, a total of 15 suppliers participated in the recycling of materials such as acrylic protective boards, cartons, pallets, trays, plastic crates, trolleys, plastic, and foam protective materials. The quantity of materials recycled accounted for 97% of the total shipment volume. - External CDP’s Recognition of Partnership

In the 2024 CDP Supplier Engagement Assessment, Coretronic received the highest rating of A (Leadership Level) for the third consecutive year. The Company is committed to strong supplier partnerships and actively engages in value chain collaboration to mitigate and adapt to climate change. The rating evaluates five categories: “Supplier Engagement”, “Targets”, “Scope 3 Emissions”, “Risk Management Process”, and “Governance and Business Strategy”. Coretronic achieved the highest rating of A (Leadership Level) in three categories: “Supplier Engagement”, “Risk Management Process”, and “Scope 3 Emissions”. Looking ahead, the Company will continue to invest in value chain management and work closely with suppliers and customers to demonstrate the highest level of operational resilience.

Local Procurement

Note: Supplier location is determined based on the registered company address.