Issue Date: September 24, 2025

Hazardous Substances Management

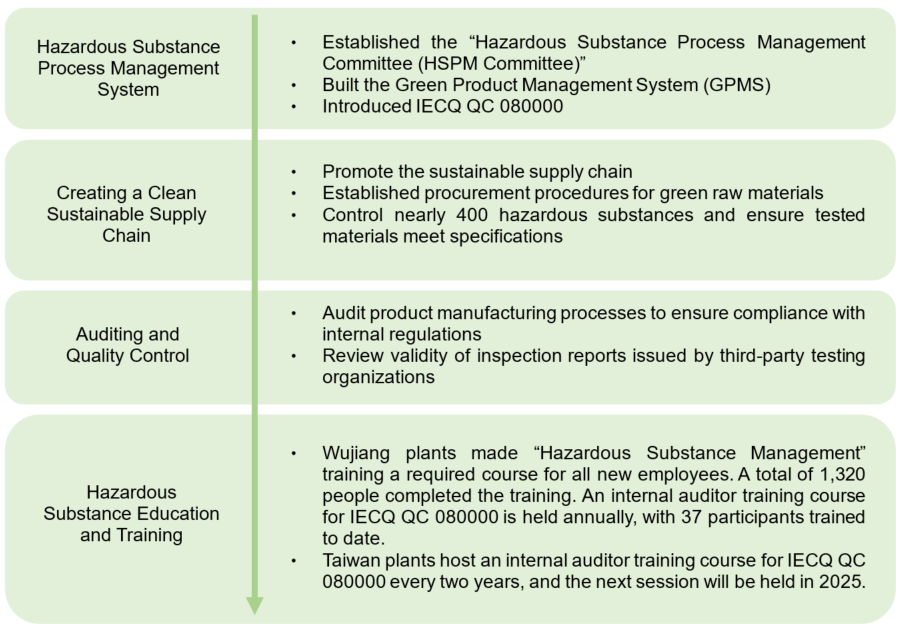

In compliance with IECQ QC 080000, the latest international regulatory trends, and customer requirements, the Company has established an ISO document titled “Green Product Specification Operating Procedure”. This document defines general requirements for prohibited and restricted hazardous substances in products (such as RoHS and REACH). Materials that meet regulatory requirements and are halogen-free are assigned specific part number identifiers and classified as “green raw materials”. This facilitates the selection of compliant materials by R&D teams during the product design stage, ensuring alignment with global regulations and the Company’s green product standards while reducing or gradually eliminating hazardous substances in products. All parts and packaging materials used in products must comply with international regulations and customer specifications regarding hazardous substances. The main controlled substances include the 10 RoHS-restricted substances, 247 REACH SVHCs, REACH Annex XVII substances, and other regulated substances under various regulations. In 2024, due to growing customer concern over per- and polyfluoroalkyl substances (PFAS), the Company initiated PFAS-related surveys and management across its supply chain in preparation for the anticipated global ban on PFAS by 2026.

There were no incidents of non-compliance with health and safety regulations related to products and services in 2024. In addition, green raw materials accounted for 96% of the Company’s total raw material procurement value.

Hazardous Substances Management Process

International Hazardous Substances Management Performance

| Key Regulatory Items | Compliance Status |

|---|---|

| Restriction of Hazardous Substances (RoHS) in various countries | Compliant |

| Halogen-free requirements | Compliant |

| EU Registration, Evaluation, Authorization, and Restriction of Chemicals (EU REACH) |

Compliant |

| Material Declaration Standard for the Electrotechnical Industry (IEC 62474) | Compliant |

| Montreal Protocol | Compliant |

| U.S. Toxic Substances Control Act (TSCA) | Compliant |

| Persistent Organic Pollutants (POPs) regulation | Compliant |

| Per/Polyfluoroalkyl substances (PFAS) | Suppliers are required to declare: “If materials contain PFAS, the R&D team will conduct alternative material screening and replacement.” |

In 2015, the Company independently developed and implemented the “Green Product Management System (GPMS)”, which incorporates a built-in Hazardous Substance-Free (HSF) management system. Green material management is carried out by the “Green Product Specifications Working Instruction”, while suppliers and contractors are required to comply with the “Green Procurement Specifications” and provide a “Green Product Warranty”. The system is integrated with the material and component approval process for effective control. Procurement contracts stipulate that materials, parts, or semi-finished products provided by suppliers must comply with hazardous substance control requirements for green products. Through sustainable supply chain management, the Company aims to promote the use of environmentally friendly materials and to manufacture and supply customers with low-toxicity and low-pollution products, thereby reducing harm to human health and the environment and preventing non-compliant materials, parts, or products from entering the Company and potentially causing ecological damage due to misuse. In addition, strengthening control over conflict minerals and ensuring that the materials purchased by suppliers better comply with RBA requirements, the Company established a “Conflict Minerals System” at the end of 2024, which is scheduled to launch officially in 2025.

Hazardous Substances Risk Assessments

Hazardous Substances Risk Assessments

Coretronic conducts annual hazardous substance risk assessments on 100% of its products (except for customer-designated components and customer-supplied materials). The following are specific practices and steps:

1. Identify hazardous substances: The Company independently developed and implemented the “Green Product Management System (GPMS)”, which incorporates a Hazardous Substance-Free (HSF) management system. Green material management is carried out by the “Green Product Specifications Working Instruction”.

2. Reference to international standards: Based on relevant laws, regulations and standards, such as the EU REACH Regulation and the RoHS Directive, the Company identifies the hazardous substances that require priority attention.

3. Supply chain management: All materials, components, or semi-finished products provided by suppliers must comply with hazardous substance control requirements for green products and be accompanied by third-party homogeneous material testing reports.

4. Hazardous substance risk assessment and analysis: Through a comprehensive analysis of hazardous substances within the product portfolio, we identify potential contaminants, including heavy metals, persistent organic pollutants (POPs), and toxic chemicals to ensure that the company's products do not pose a risk to human health or the environment.

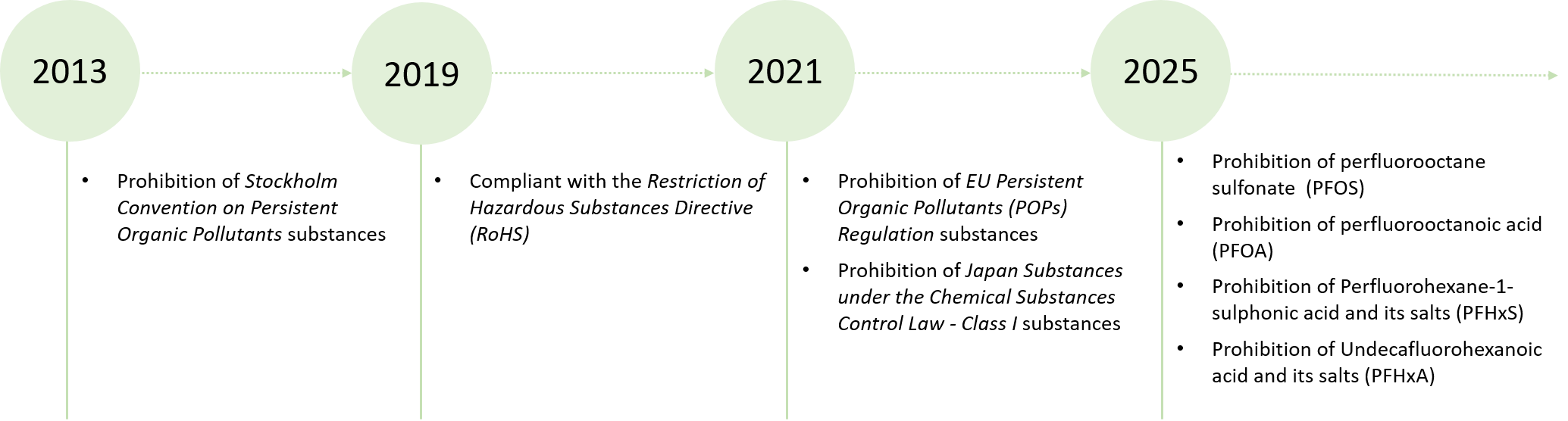

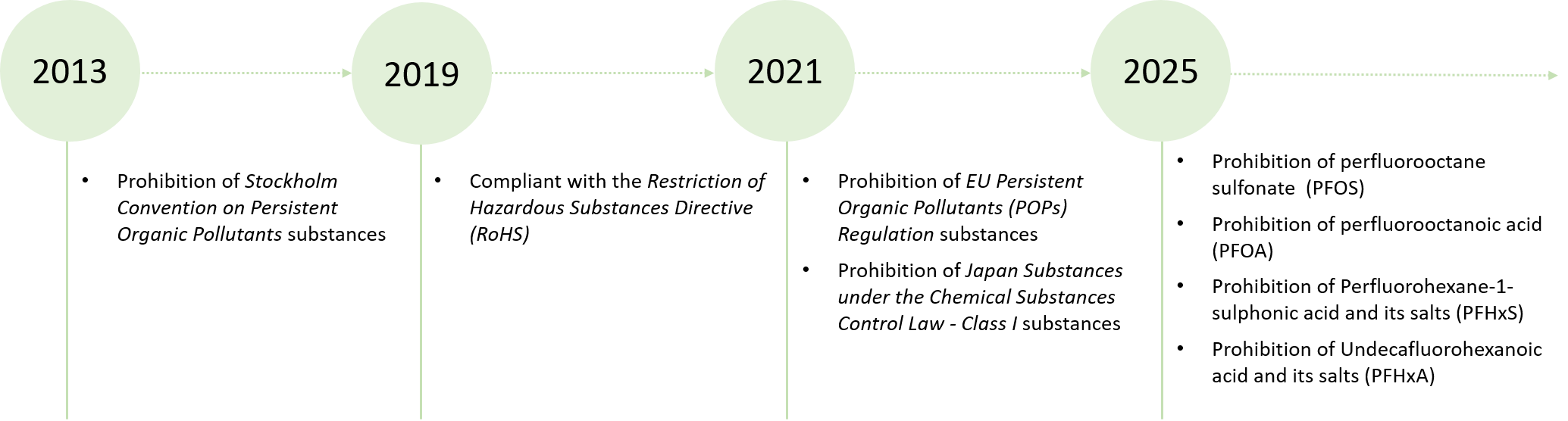

Progress in Phasing Out Hazardous Substances

1. Identify hazardous substances: The Company independently developed and implemented the “Green Product Management System (GPMS)”, which incorporates a Hazardous Substance-Free (HSF) management system. Green material management is carried out by the “Green Product Specifications Working Instruction”.

2. Reference to international standards: Based on relevant laws, regulations and standards, such as the EU REACH Regulation and the RoHS Directive, the Company identifies the hazardous substances that require priority attention.

3. Supply chain management: All materials, components, or semi-finished products provided by suppliers must comply with hazardous substance control requirements for green products and be accompanied by third-party homogeneous material testing reports.

4. Hazardous substance risk assessment and analysis: Through a comprehensive analysis of hazardous substances within the product portfolio, we identify potential contaminants, including heavy metals, persistent organic pollutants (POPs), and toxic chemicals to ensure that the company's products do not pose a risk to human health or the environment.

Progress in Phasing Out Hazardous Substances