Issue Date: July 18, 2025

Coretronic also actively collaborates with customers to implement the concept of product recycling and reuse. Through machine recycling, material refurbishment, and performance enhancement, the Company restores product performance and reuses the products, significantly reducing the use of raw materials and extending the product life cycle. Furthermore, the Comapny has established a robust green supply chain with suppliers, requiring them to meet environmental standards and jointly reducing the environmental impact of the supply chain. These diverse green product strategies not only meet market and customer demands, but also effectively reduce product carbon footprints. Looking ahead, Coretronic aims to lead the green product trend and offer a wider range of environmentally friendly solutions to the global market.

-

Project Teams

- Green Projector Development Team: The highest executives of the mainstream, commercial, and smart projector business groups appointed the R&D managers to form the Green Product Development Team. This team leads a comprehensive review of the carbon emissions generated during the projector product development and design processes. Implementing environmentally friendly designs based on the product characteristics and advantages, gradually conducting product carbon footprint inventories and establishing a comprehensive product carbon footprint database. Through continuous product optimization and performance enhancement, aiming to achieve carbon reduction targets.

- Green Product R&D Team: With green design as its core concept, this team focuses on developing products with features such as “low energy consumption”, “lightweight design”, and the “use of recycled materials”. In 2024, the team regularly held working group meetings and initiated 34 product development projects. These included integrating recycled aluminum back panels and recycled plastic frames into new products, as well as developing high-efficiency backlight modules to reduce energy consumption. The team also continued to implement low-carbon technologies for light guide plates and lightweight optical films in mass production to meet customer needs. - Product Carbon Footprint Inventory

- Product Carbon Footprint Inventory Platform: Based on the inventory results of the EX1 laser projector platform, the Company has independently planned and established a product carbon footprint inventory platform aligned with product BOM data. In 2024, the “Material Emission Factor Database” was completed, which prioritizes the verification of carbon emission data for new product components. The “Manufacturing Stage Database” is scheduled for completion in 2025, with full platform deployment targeted for 2026.

- ISO 14067 Verification: In 2022, three mainstream EX1 laser projector models, one 15-inch LCD monitor model, and one 43-inch LCD monitor model were selected for ISO 14067 B2B product carbon footprint inventory and verification. According to the carbon footprint inventory of the EX1 laser projectors, the most significant emission phase was the B2B “raw material acquisition” stage. Moving forward, the Company will utilize its in-house carbon footprint inventory platform to identify emission hotspots and focus on raw material substitution, low-carbon material selection, and recycled material adoption. These actions aim to optimize product design and continuously develop sustainable, green products with competitive advantages for consumers.

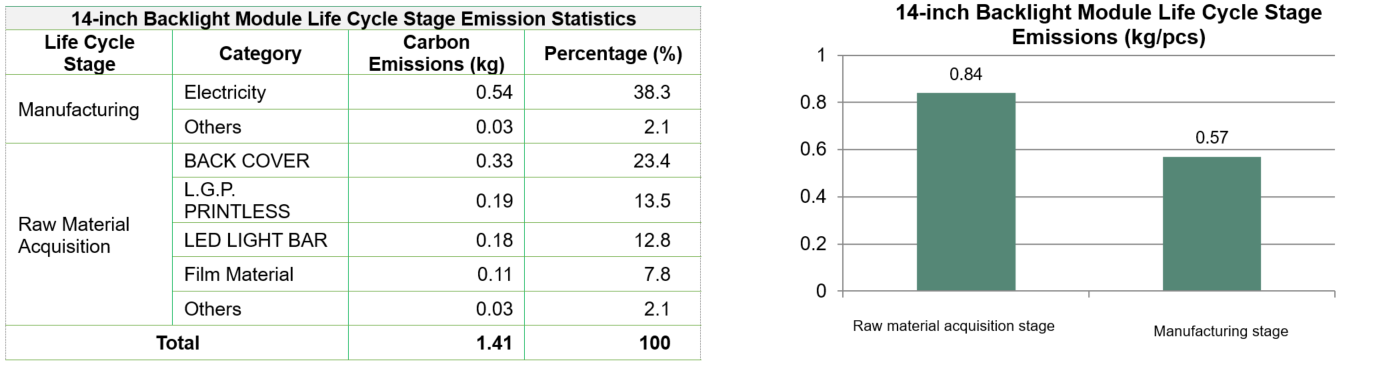

- Self-Conducted Inventory: Since 2016, the Company has independently conducted carbon footprint inventories for its backlight module products for nine consecutive years. In 2024, the carbon footprint of a 14-inch backlight module was 1.41 kgCO₂e per unit, a 25% reduction compared to 2023. This improvement was primarily due to a 38% reduction in electricity consumption per unit, a 21% reduction in back panel weight, a 35% reduction in production time, and an 11% decrease in plant electricity usage. The Company will continue promoting green product development, diverse energy-saving initiatives, and increased renewable energy use to support the development of low-carbon products.

Green Design

- R&D Patents: Green thinking is integrated into R&D technologies, and active patent applications are pursued to design green products that help customers save energy and reduce carbon emissions. In 2024, 58% of the proposals at Taiwan plants were related to energy conservation and carbon reduction.

- Projectors and Visual Solutions

- Continued optimization of the optical design of mainstream projectors has significantly enhanced overall product performance. Compared to 2023, energy efficiency improved by 74%, with an estimated annual electricity savings of 44.29 GWh, equivalent to a carbon reduction of 21,877 metric tons.

- Solid-state light source (SSI) projectors are more energy-efficient than lamp-based projectors. The EX/EU laser projector series platform models consume 54% less energy than comparable lamp-based models.

- Certain models of smart projectors use solar-powered remote controls and reduce material usage for individual components by 50%, effectively lowering raw material consumption and environmental impact.

- In collaboration with customers, the D32 platform key component revitalization program was launched. This program enhances key component quality through core technologies, enabling easier disassembly and recycling. Recycled components can be reintegrated into the production process, achieving a 60% reuse rate.

- Power consumption in standard operation and standby modes complies with EU energy-saving standards.

- Equipped with an automatic power-off safety feature (including automatic power-off for no signal source and sleep mode).

- Reduced the need for post-processing designs (such as electroplating, painting, printing) depending on the product category.

- Adopted environmentally friendly solid-state light sources (SSI) such as LED and laser, as well as other mercury-free materials, to introduce completely mercury-free projectors.

- Compared to traditional lamp projectors, the lifespan of the light source in LED and laser projectors can be up to 5 times longer, eliminating the need for lamp replacement and reducing environmental impact. - Backlight Modules and Energy Saving Products

- Development of High-Efficiency Backlight Modules to Reduce Energy Consumption: By optimizing the optical film materials and microstructure design of the light guide plate, the light emitted from the light guide plate can achieve higher efficiency through the optical films, effectively reducing energy consumption. The newly developed LCD modules in 2024 achieved an energy-saving rate of 5.3%.

- Low-Carbon Backlight Board Technology: The Tainan Plant 1 enhanced optical brightness technology, resulting in a 25% reduction in lighting power consumption. In 2024, 62,292 units were produced. Assuming 10 hours of daily use over 365 days, this led to an electricity saving of over 1.89 GWh and a carbon reduction of 934 metric tons.

- Lightweight Backlight Board Design: The Tainan Plant 1 reduced the thickness of composite optical films and redesigned structural components, lowering the material usage of optical films and back plates. The average weight was reduced by approximately 7%. In 2024, 486,480 units were produced, achieving a total weight reduction of 36 metric tons, which translates to a carbon reduction of 73 metric tons.

- Lightweight Optical Film Design: Coretronic Optotech (Suzhou) optimized the optical structural design, replacing the original 0.45 mm POP film with a 0.32 mm MOP film while maintaining optical performance. This lightweight design reduced the weight by about 31%. In 2024, 1,083 units of small-sized lightweight products were introduced, reducing the overall product weight by 5 kg, with a carbon reduction of 0.01 metric tons.

- Optimized Circuit Design: Coretronic Optics (Suzhou) implemented a circuit optimization project for a 14.9-inch automotive touch display module, reducing the number of flexible flat cables (FFC) from 6 to 4. In 2024, 2,700 touch display modules were produced, resulting in a carbon reduction of 0.05 metric tons.

Low-Carbon Materials

To align with international sustainability trends and customer requirements and to effectively reduce Scope 3 GHG emissions, Coretronic has established the “Sustainable Raw Material Policy” following discussions by the Green Projector Development Team and Green Product R&D Team. The policy aims to “increase the use of recycled raw materials”, “achieve a 30% absolute reduction in Scope 3 GHG emissions by 2032”, and reach “net-zero emissions by 2050”. The policy was signed by the Chairman and publicly announced on the official website.

- To reduce raw material consumption and promoting a circular economy, the Company has used 50% post-consumer recycled plastic (PCR) for product casings since 2022. In 2024, the number of PCR-integrated models for mainstream and commercial projectors continued to increase, with PCR-equipped units accounting for 12% of the total annual shipments in these two categories, achieving the short-term target.

- The projector models utilizing PCR consumed a total of 59 metric tons of plastic, of which 19.7 metric tons were PCR, representing 33% of the total plastic used.

- In collaboration with customers, recycled aluminum materials were added to the back covers of newly developed laptop models. The proportion of models using recycled aluminum has been gradually increased, and in 2024, 3.8% of newly developed laptop models incorporated recycled aluminum, achieving the short-term target.

- The newly developed laptop models that used recycled aluminum consumed a total of 7.756 metric tons of aluminum, including 0.0222 metric tons of recycled aluminum, accounting for 0.29% of the total aluminum used.

Green Manufacturing

- Chunan Plant adjusted the production temperature in the light guide plate process, saving 0.25 kWh of electricity per hour. In 2024, with a total of 3,466 production hours, this resulted in a saving of 867 kWh of electricity and a carbon reduction of 0.4 metric tons.

- Coretronic Optics (Suzhou) continued adopting cold bending process to replace the traditional hot bending process. By applying cold bending to 12.3-inch automotive touch display materials, carbon emissions per unit area were reduced by 30%. In 2024, a total of 68,000 displays were produced, with a processed area of 36,627 square feet, resulting in a carbon reduction of 549 metric tons.

- Following local regulatory requirements under the “National Pollution Prevention and Control Technology Guidance Catalogue (2024, Restricted and Eliminated Categories)”, Coretronic Optics (Suzhou) phased out the UV photolysis exhaust gas treatment process, saving 31,500 kWh of electricity and reducing 17 metric tons of carbon emissions in 2024.

- Due to organizational restructuring, Kunshan plants integrated production processes, resulting in a savings of 74,880 kWh of electricity and a carbon reduction of 42.7 metric tons in 2024.

Green Packaging

- Eco-friendly cushioning materials: For mainstream and smart projector shipments, paper pulp and folded paper eco-packaging materials were used as cushioning. These environmentally friendly materials were used in 90% of annual shipments for these two projector categories.

- Use of recycled pulp cartons for shipments: Projectors are shipped in cartons made from FSC-certified or recycled pulp-based paperboard products, covering 96% of total projector shipments annually.

- Reprocessing of discarded trays: Once trays have been reused multiple times and no longer meet quality standards, they are fully returned to the tray supplier for remanufacturing. This approach aims to achieve waste-to-resource conversion, replacement of natural resource extraction, complete material circulation, and zero waste. In 2024, 1,185 discarded trays were remanufactured, reducing 0.1 metric tons of waste and 0.2 metric tons of carbon emissions.

Green Transportation

- The overall volume design of mainstream laser projectors was optimized, reducing average dimensions by 36%, resulting in an estimated annual carbon reduction of approximately 2.7 metric tons.

- To balance timeliness with carbon reduction, some cargo originally scheduled for air freight was shipped via sea freight instead, leading to a carbon reduction of nearly 2.9 metric tons in 2024.

- Sustainable aviation fuel adoption: For two consecutive years, DHL's “GoGreen Plus Sustainable Air Transport Solution” has been adopted, using sustainable aviation fuel (SAF) to reduce carbon emissions. In 2024, the total carbon emissions amounted to 50.03 metric tons, representing a reduction of 45.38 metric tons compared to conventional air freight, which is equivalent to a 48% decrease in carbon emissions.